If you’re looking for guidance on how to glue polyethylene, this article will provide you with essential information. Polyethylene is a commonly used plastic, and knowing how to glue it effectively can benefit various projects. Polyethylene is a versatile material commonly used in packaging, construction, and automotive industries. Knowing how to glue polyethylene can be challenging due to its low surface energy and resistance to solvents. But worry not! You can achieve a strong and durable bond with the right approach and knowledge.

This guide will explore different types of adhesives suitable for polyethylene, including epoxy, cyanoacrylate, and hot melt glue. We’ll also discuss the importance of surface preparation and provide step-by-step instructions for achieving optimal results, especially when working with specialized materials like polyethylene foam. Whether you’re a DIY enthusiast or a professional in the manufacturing industry, this guide is guaranteed to help you navigate the world of gluing polyethylene with confidence. Let’s start and master the art of bonding polyethylene like a pro!

Understanding the challenges of gluing polyethylene

Gluing polyethylene presents unique challenges primarily due to its chemical properties. When learning how to glue polyethylene, it’s crucial to understand that this thermoplastic polymer is known for its low surface energy, which makes it difficult for adhesives to create a strong bond. Many common adhesives struggle to adhere properly to polyethylene, often resulting in weak bonds that can fail under stress.

Moreover, polyethylene is susceptible to various environmental factors that can impact adhesive bonding. Temperature changes, UV radiation, and moisture can all affect the longevity of the adhesive bond. For instance, the material’s sensitivity to these conditions means that any polyethylene glue must not only bond well but also withstand potential environmental stresses. This complexity underscores the importance of selecting the right polyethylene adhesive and preparation techniques.

Best Glue for Polyethylene: Top Adhesive Choices for Strong Bonds

Finding the “best glue for polyethylene” can be challenging due to its unique, low-surface-energy properties. However, with advancements in adhesive technology, several types of glues stand out for their ability to create strong, lasting bonds with this notoriously difficult plastic. Understanding these top contenders is crucial for anyone working with PE, from DIY enthusiasts to industrial professionals looking for a reliable polyethylene plastic glue.

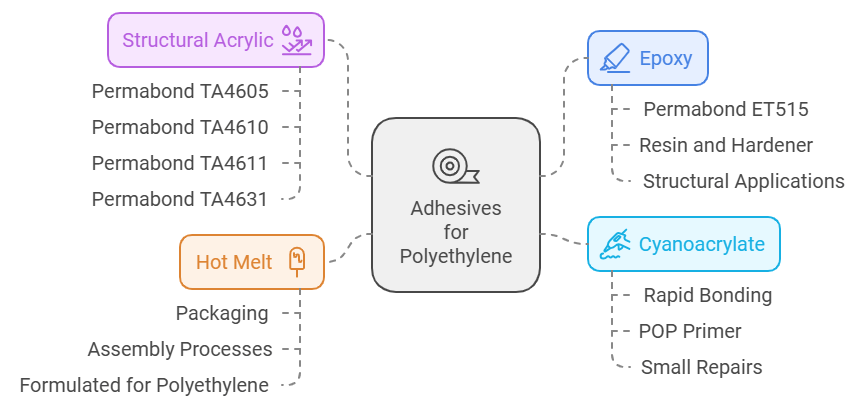

The most effective adhesives for polyethylene are generally those specifically formulated to overcome its inherent resistance to bonding. Here are the leading options for successful polyethylene bonding:

- Structural Acrylic Adhesives: Often considered among the best adhesive for polyethylene, specialized structural acrylic adhesives are engineered to bond low-surface-energy plastics like polyethylene without extensive surface preparation beyond cleaning. Products like Permabond’s TA4605, TA4610, TA4611, and TA4631 offer excellent impact and environmental resistance, making them ideal for demanding applications where durability is key. These adhesives create a robust, resilient bond, providing a superior polyethylene adhesive

- Two-Part Epoxies (with Surface Treatment): While standard epoxies may struggle, certain flexible epoxy formulations, such as Permabond ET515, can provide excellent adhesion to polyethylene, especially when combined with proper surface treatment. For specific heavy-duty repairs or construction, products like TAP Poly Weld, a two-part epoxy adhesive, are highly effective. Crucially, these epoxies often require flame treatment of the polyethylene surface to modify its molecular structure and enhance receptiveness to the glue, ensuring a strong, durable connection, even when asking how to glue HDPE.

- Cyanoacrylate Adhesives (Super Glues) with Primer: For quick, small repairs where high structural strength isn’t the primary concern, specialized cyanoacrylate (super glue) formulations can work. However, their effectiveness on polyethylene is significantly boosted by the use of a primer specifically designed for low-surface-energy plastics. Primers like Permabond POP Primer enable cyanoacrylates to form a bond by reacting with moisture in the air, offering a fast-acting solution. Without a primer, standard super glues will likely fail to bond effectively to polyethylene.

- Hot Melt Adhesives (PE-Specific Formulations): Commonly used in packaging and assembly, hot melt adhesives can provide a strong bond for polyethylene. The key here is to select a hot melt adhesive specifically formulated for polyethylene. These specialized formulations are designed to adhere to PE upon cooling and solidification, offering a quick and efficient bonding method for various applications.

Key Considerations for Choosing the Best Glue:

When selecting the best glue for polyethylene for your project, consider the following:

- Application Requirements: What level of bond strength, flexibility, and environmental resistance do you need from your polyethylene glue?

- Surface Preparation: Are you able to perform surface treatments like flame treatment, or do you need an adhesive that bonds with minimal preparation? This is particularly relevant when considering how to glue HDPE.

- Curing Time: How quickly do you need the bond to set and cure?

By understanding the strengths of these top adhesive types and considering your project’s specific needs, you can confidently choose the best glue to achieve a strong and lasting bond with polyethylene.

Types of Adhesives Suitable for Polyethylene

When it comes to bonding polyethylene, various types of adhesives can be effective, each with unique properties suited for specific applications. Choosing the right polyethylene adhesive is crucial for achieving a strong and durable bond.

One of the most popular choices is epoxy adhesive. Epoxies are known for their strength and versatility, offering excellent adhesion to polyethylene when properly applied. Specific examples like Permabond ET515 provide a flexible epoxy solution that is particularly suitable for polyethylene applications. These adhesives typically consist of a resin and a hardener that, when mixed, chemically react to form a tough, durable bond. Epoxies can be ideal for structural applications, providing a strong hold under various environmental conditions for polyethylene bonding.

Cyanoacrylate (super glue) offers another bonding option. This fast-acting adhesive forms a bond by reacting with moisture in the air, making it suitable for small, quick repairs on polyethylene. While cyanoacrylate offers rapid bonding capabilities, it may not be as durable under stress or extreme conditions as epoxy. Companies like Permabond offer specialized primers, such as the POP Primer, which can enhance cyanoacrylate adhesion to polyethylene, improving its performance as a polyethylene plastic glue.

Hot melt adhesives are also commonly used for polyethylene applications. These adhesives are applied in a molten state and solidify upon cooling, creating a bond as they harden. They can provide a strong bond for various applications, especially in packaging and assembly processes. However, it is vital to select a hot melt adhesive specifically formulated for polyethylene.

A noteworthy recent development is the introduction of structural acrylic adhesives specifically designed for polyethylene. Permabond has developed a line of specialty adhesives, including TA4605, TA4610, TA4611, and TA4631. These adhesives bond low surface energy plastics and offer good impact and environmental resistance, making them an excellent option for rugged applications where a reliable polyethylene adhesive is needed.

For specific polyethylene repair and construction projects, products like TAP Poly Weld provide targeted solutions. This two-part epoxy adhesive requires flame treating the polyethylene surface to create a strong bond, making the polyethylene molecules more receptive to the polyethylene glue. This method is often employed when considering how to glue HDPE effectively.

Preparing the Polyethylene Surface for Gluing

Surface preparation is a critical step in ensuring a successful bond when gluing polyethylene. The first step in this process is cleaning the surface thoroughly to remove any contaminants such as dirt, oil, or dust. Using a mild detergent and warm water, scrub the polyethylene surface gently. After cleaning, rinse the surface with clean water and allow it to dry completely. This initial cleaning helps remove any barriers that may interfere with adhesive bonding and creates a clean slate for the polyethylene adhesive to adhere to.

In addition to mechanical surface preparation, several advanced surface treatment techniques can significantly improve adhesion. Corona treatment uses a high-voltage electrical discharge to modify the polyethylene surface, increasing its wettability and adhesion properties. Similarly, plasma treatment employs an ionized gas to alter the surface chemistry, enhancing bonding capabilities.

Flame treatment offers another effective surface preparation method, often vital when determining the best adhesive for polyethylene. This technique involves briefly exposing the polyethylene surface to a flame, typically from a propane torch. The goal is to oxidize the surface without melting the plastic, with the yellow part of the flame being most effective. A simple water bead test can verify the treatment’s success: if water beads up, the treatment is insufficient; if the water sheets or flattens, the surface is ready for bonding polyethylene. This step is particularly important when learning how to glue HDPE.

Traditional Joining Methods for Polyethylene

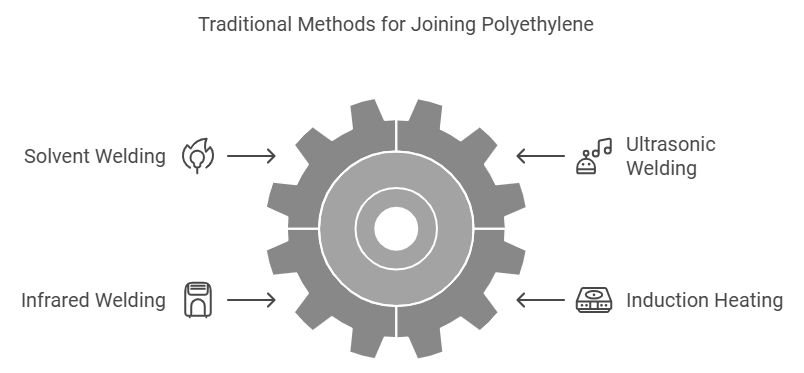

While adhesive bonding is versatile, polyethylene’s unique properties also make it suitable for several traditional joining methods. These techniques can be particularly effective when joining polyethylene to itself:

- Solvent welding: This method involves using a solvent to soften the polyethylene surfaces, allowing them to fuse together.

- Ultrasonic welding: Using high-frequency vibrations to generate heat and melt the polyethylene at the joint interface, creating a weld.

- Infrared welding: Employing infrared radiation to heat and melt the polyethylene surfaces, facilitating bonding.

- Induction heating: Utilizing electromagnetic induction to heat the polyethylene, enabling welding or bonding.

These methods are most effective for joining polyethylene to itself. When bonding polyethylene to different substrates, industrial adhesive bonding becomes the preferred approach, often requiring a specialized polyethylene glue.

Step-by-step Guide to Gluing Polyethylene

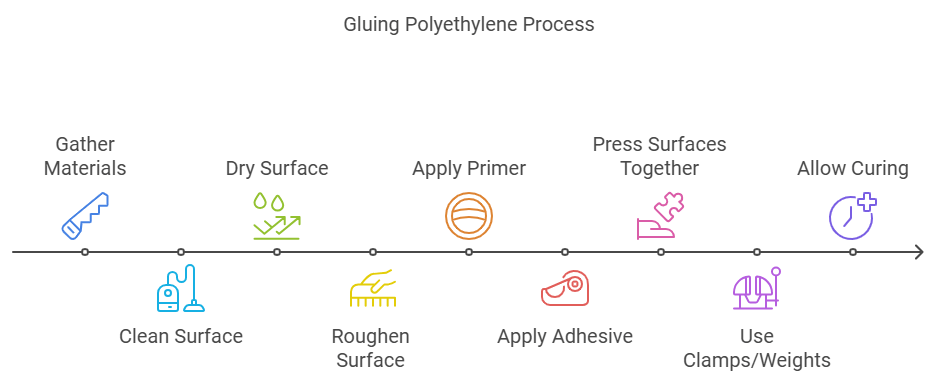

To successfully glue polyethylene, follow this step-by-step guide to ensure you achieve a strong bond. First, gather all necessary materials, including the polyethylene pieces to be bonded, the chosen polyethylene adhesive, cleaning supplies, sandpaper, and any additional tools you may need, such as clamps or weights for holding the pieces in place while the adhesive cures. Having everything ready will streamline the process and help you avoid any interruptions during application.

Begin by cleaning the polyethylene surface thoroughly, as previously discussed. Once clean, dry the surface completely to prevent moisture from interfering with the adhesive bond. After the surface is prepared, use sandpaper to lightly roughen the areas where the polyethylene glue will be applied. This step increases the surface area for the adhesive to grip, enhancing the bond’s strength. Be careful not to overdo this step, as excessive abrasion can weaken the polyethylene itself.

Next, if using a primer, apply it to the roughened surfaces of the polyethylene according to the manufacturer’s instructions. Allow the primer to dry completely before proceeding to the next step. Once the surfaces are prepared and dry, apply the adhesive evenly to one surface, ensuring that you cover the area adequately without excessive overflow. Press the two surfaces together firmly and use clamps or weights to hold them in place if necessary. Allow the polyethylene adhesive to cure fully, following the recommended curing time provided by the adhesive manufacturer. This methodical approach will help you achieve a strong and durable bond when bonding polyethylene.

When selecting an adhesive, consider specialized options like structural acrylic adhesives or two-part epoxies designed specifically for polyethylene. For some adhesives like TAP Poly Weld, you may need to perform additional surface treatments such as flame treating to ensure optimal polyethylene bonding. This is a common consideration for how to glue HDPE.

Common Mistakes to Avoid When Gluing Polyethylene

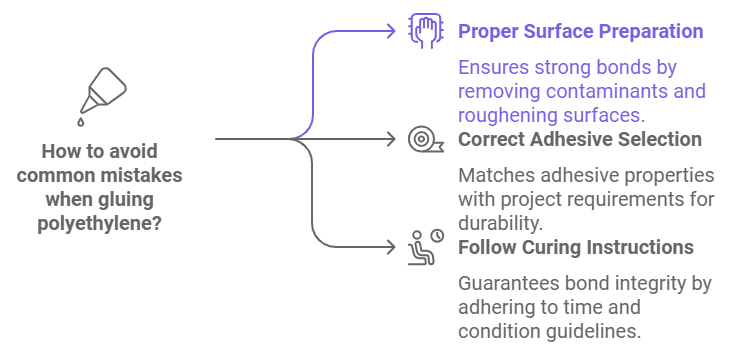

When gluing polyethylene, avoiding common mistakes can significantly impact the success of your project. One frequent error is neglecting proper surface preparation. Many people underestimate the importance of cleaning and roughening the surface before applying polyethylene glue. Skipping these steps can result in weak bonds that fail under stress. Always ensure that surfaces are clean, dry, and suitably prepared to maximize adhesive effectiveness for polyethylene bonding.

Another mistake to avoid is using the wrong type of polyethylene adhesive for the application. Different adhesives have varying properties, and not all are suitable for polyethylene. For instance, using a standard super glue may not provide the strength needed for heavy-duty applications. Always read the manufacturer’s recommendations to ensure that the adhesive is appropriate for use with polyethylene. Selecting the correct polyethylene plastic glue will not only enhance the bond’s strength but also ensure durability under various conditions.

Additionally, failing to follow the curing instructions can lead to bond failure. Each adhesive has specific curing times and conditions that must be adhered to for optimal results. Rushing the process by handling the bonded pieces too soon can compromise the bond’s integrity. Always allow sufficient time for the adhesive to cure completely, and avoid applying stress to the bond until it has fully set. By steering clear of these common pitfalls, you can enhance the likelihood of achieving a successful bond when working with polyethylene. This applies whether you’re bonding polyethylene or figuring out how to glue HDPE.

Tips and Tricks for Successful Polyethylene Gluing

dhesives may set quickly, many require additional time to achieve maximum strength. By maintaining pressure on the bond, you can prevent any movement that could weaken the adhesive’s grip. Using clamps ensures that the pieces remain aligned, providing a more uniform bond. Following these tips can help you achieve successful and durable bonds when working with polyethylene, proving that polyethylene bonding is achievable.

For a comprehensive approach, it’s better to read this article on how to paint polyethylene plastic. This will give you additional insights into preparing and finishing your polyethylene projects for optimal results. Proper surface preparation and the right painting techniques can enhance your polyethylene items’ appearance and durability.

Best Practices for Long-Lasting Adhesive Bonds on Polyethylene

To ensure long-lasting adhesive bonds on polyethylene, adopting best practices is essential. Start with comprehensive surface preparation, as this is the foundation for a strong bond. Cleaning, roughening, and priming the surfaces will significantly improve the polyethylene adhesive’s ability to grip the polyethylene. Always use the appropriate cleaning agents and abrasives to avoid damaging the material, and ensure that the surfaces are completely dry before polyethylene glue application.

Choosing the right polyethylene adhesive is equally important. Be sure to select an adhesive specifically designed for polyethylene or one that has demonstrated effectiveness with this type of plastic. Read product labels and manufacturer recommendations to confirm suitability for your project. This is key to finding the best adhesive for polyethylene. Additionally, consider the environmental conditions that the bonded polyethylene will be exposed to, such as temperature fluctuations and moisture levels, and select an adhesive that can withstand these conditions, whether you’re bonding polyethylene or learning how to glue HDPE.

Finally, allow ample time for the polyethylene glue to cure fully before putting any stress on the bond. Each adhesive has a specified curing time that must be respected for optimal bond strength. Avoid rushing this process, as premature handling can lead to bond failure. Maintaining stable conditions during the curing phase, such as avoiding vibration or movement, will also contribute to achieving a reliable and long-lasting bond on polyethylene.

Safety Precautions When Working with Adhesives

When working with adhesives, especially those used for gluing polyethylene, safety should always be a priority. Begin by reading the safety data sheets (SDS) for the specific polyethylene glue you are using. These documents provide essential information about the potential hazards, handling instructions, and first aid measures. Familiarizing yourself with this information will help you take the necessary precautions while working with the adhesive.

Personal protective equipment (PPE) is crucial when handling adhesives. Wear safety glasses to protect your eyes from splashes or fumes, and consider using gloves to prevent skin contact with the adhesive. Some adhesives can be irritating or harmful upon contact with the skin, so using appropriate gloves will provide an extra layer of protection. Additionally, ensure that you are working in a well-ventilated area to minimize inhalation of fumes, as some adhesives can release volatile organic compounds (VOCs) that may be harmful if inhaled.

Lastly, keep all adhesives stored safely and out of reach of children and pets. Ensure that containers are tightly sealed when not in use to prevent spills or accidental exposure. Dispose of any unused polyethylene adhesive according to local regulations, and do not pour adhesives down the drain or into the environment. By following these safety precautions, you can create a safer working environment while effectively bonding polyethylene.

Conclusion: Achieving Strong and Durable Bonds with Polyethylene

In conclusion, successfully gluing polyethylene requires a thorough understanding of the material’s properties and the challenges associated with bonding it. By selecting the appropriate polyethylene adhesive and following the recommended surface preparation techniques, you can significantly enhance the strength and durability of the bond. Recognizing common mistakes and implementing best practices will further increase your chances of achieving a reliable bond that withstands the test of time.

Remember that patience is key when working with adhesives. Allowing adequate curing time and creating optimal conditions for polyethylene bonding can make a considerable difference in the final results. With the tips and tricks shared in this guide, as well as proper safety precautions, you can approach your polyethylene bonding projects with confidence and skill.

Whether you’re a DIY enthusiast or a professional in the field, mastering the art of gluing polyethylene will open up a world of possibilities for your projects. With practice and attention to detail, you can achieve strong, durable bonds that meet your needs and exceed your expectations. So gather your materials, prepare your surfaces, and get ready to bond polyethylene like a pro, whether you need a strong polyethylene plastic glue or want to know how to glue HDPE!

Frequently Asked Questions about Gluing Polyethylene

- Is it possible to glue polyethylene? Yes, it is possible to glue polyethylene, but it presents unique challenges due to its low surface energy. Traditional glues often fail to bond effectively. Success hinges on using specialized polyethylene adhesive types, such as structural acrylics or specific epoxies, often combined with proper surface preparation techniques like flame treatment, to ensure strong polyethylene bonding.

- What is the best adhesive for polyethylene? The best adhesive for polyethylene often depends on the specific application and whether you can perform surface preparation. Generally, specialized structural acrylic adhesives (e.g., Permabond TA series) are highly effective without extensive pre-treatment. Two-part epoxies can also work very well, especially if the polyethylene surface is flame-treated. For quick fixes, cyanoacrylates (super glues) require a specific primer to bond to polyethylene.

- Can I use super glue (cyanoacrylate) on polyethylene? Standard super glue (cyanoacrylate) will generally not create a strong, lasting bond on polyethylene on its own. Its effectiveness is significantly improved by using a primer specifically designed for low-surface-energy plastics (like Permabond POP Primer) before applying the cyanoacrylate. This primer modifies the surface, allowing the super glue to adhere.

- How do I prepare polyethylene for gluing? Proper surface preparation is critical for polyethylene bonding. Start by thoroughly cleaning the polyethylene surface to remove dirt, grease, or contaminants. After cleaning, roughening the surface with fine-grit sandpaper can help. For optimal adhesion, advanced techniques like flame treatment, corona treatment, or plasma treatment are highly recommended. A simple water bead test can verify if the surface is ready after treatment.

- What is the process for gluing HDPE (High-Density Polyethylene)? Gluing HDPE follows the same principles as gluing polyethylene in general, as HDPE is a type of polyethylene. The most effective methods for how to glue HDPE involve using specialized polyethylene glue such as structural acrylics or two-part epoxies. Crucially, flame treatment is often essential for preparing the HDPE surface to accept the adhesive, creating a durable bond.

- Can hot melt glue be used for polyethylene? Yes, hot melt adhesives can be used for polyethylene, especially in applications like packaging or assembly. However, it is essential to use a hot melt adhesive specifically formulated for polyethylene. These specialized formulations are designed to bond effectively as they cool and solidify on the PE surface.

- Why is polyethylene difficult to glue? Polyethylene is difficult to glue primarily because of its low surface energy. This means its surface is non-polar and doesn’t “wet” easily, making it hard for liquid adhesives to spread and form a strong molecular bond. Its chemical inertness and resistance to solvents also contribute to this challenge, which is why specialized polyethylene adhesive is needed.

- What alternatives are there if adhesives don’t work for my polyethylene project? If adhesive bonding isn’t suitable or fails for your polyethylene project, consider traditional joining methods. These include solvent welding (for compatible PE types), ultrasonic welding, infrared welding, or induction heating. These methods are typically used for bonding polyethylene to itself, rather than to different materials.

درج دیدگاه