If you’re looking for a durable and versatile bag that can meet all your packaging needs, look no further than polypropylene bags. In this ultimate guide, we’ll delve into everything you need to know about these highly popular bags.

what is a polypropylene bag? Polypropylene bags, also known as PP bags, are made from the synthetic polymer polypropylene. Their elegant simplicity and wide range of uses have made them a staple in various industries. Whether you’re in the retail, food, or manufacturing sector, polypropylene bags offer unparalleled benefits.

In this comprehensive guide, we’ll explore the different types of polypropylene bags available and their specific applications. We’ll also discuss the key advantages they offer, including their durability, resistance to moisture and chemicals, and their eco-friendly nature.

Furthermore, we’ll delve into the important factors to consider when choosing polypropylene bags, such as bag thickness, size, and closure options. You’ll learn how to select the right bag that aligns with your specific requirements.

Different Types of Polypropylene Bags

Polypropylene bags are not a one-size-fits-all solution. They come in various forms, each tailored for specific purposes:

- FIBC bags (Flexible Intermediate Bulk Containers): Designed to hold large quantities of materials, typically up to 2,000 pounds, these bags come in various configurations including duffle top, spout top, and versions with baffles for added stability. They are crucial in multiple industries, finding extensive use in agriculture for moving feed and harvested food, in food packaging for transporting large ingredient quantities, and at construction sites for moving and storing materials.

- BOPP bags (Biaxially Oriented Polypropylene): These bags undergo a unique stretching process in two directions, enhancing their strength, clarity, and printability. The biaxial orientation creates a glossy appearance that makes them stand out on shelves. Their exceptional properties include waterproofing, resistance to grease and oils, and the ability to showcase detailed printed graphics. These characteristics make BOPP bags particularly ideal for food packaging, ensuring product freshness and preserving critical labelling information.

- Gusseted bags: These bags have an additional panel that allows them to stand upright, making them suitable for product display and storage.

- Lined bags: For applications requiring extra protection from moisture, polypropylene bags can be lined with plastic film or foil.

- Retail shopping bags: Woven polypropylene bags have become popular as reusable grocery bags due to their durability and sustainability.

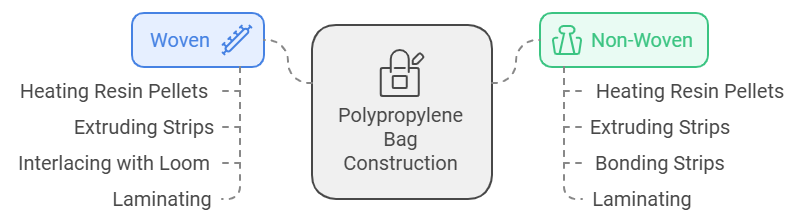

How are Polypropylene Bags Made?

Polypropylene bags are constructed by weaving together strips of polypropylene, resulting in a lightweight yet remarkably strong material. The process begins with heating polypropylene resin pellets and extruding them into thin, flat strips. For woven polypropylene bags, these strips are interlaced using an industrial loom, forming a fabric with a distinctive warp and weft pattern. The resulting fabric is then cut and sealed or sewn to create the final bag.

In the case of non-woven polypropylene bags, the strips are bonded together, creating a smoother, fabric-like material. Both woven and non-woven bags can be laminated to enhance their durability and printability.

Properties and Characteristics of Polypropylene Bags

Polypropylene bags are renowned for their unique properties, which make them an ideal choice for a variety of applications. One of the most significant characteristics of these bags is their remarkable strength. Made from a thermoplastic polymer, polypropylene has a high tensile strength, meaning it can withstand considerable weight and pressure without tearing or breaking. This strength is particularly beneficial in industries where heavy products need to be transported or stored, ensuring that the bags maintain their integrity under load.

Another notable property is the bags’ resistance to moisture and chemicals. Polypropylene is inherently hydrophobic, meaning it does not absorb water. This feature allows the bags to keep their contents dry, making them ideal for storing items that are sensitive to moisture. Additionally, polypropylene bags can resist a wide range of chemicals, making them suitable for packaging products in the agricultural, chemical, and food industries where exposure to such substances is common.

The lightweight nature of polypropylene bags is yet another characteristic that adds to their appeal. Despite their strength, these bags are incredibly lightweight, allowing for easy handling and transportation. This quality not only makes them cost-effective in terms of shipping but also contributes to reducing carbon footprints during logistics. Furthermore, the versatility in design and printing options provides businesses the opportunity to customize these bags to align with their branding, enhancing visual appeal and recognition in the marketplace.

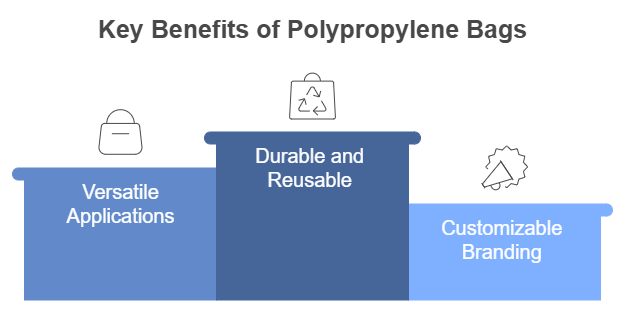

Benefits of Using Polypropylene Bags

The benefits of using polypropylene bags extend far beyond their inherent properties. First and foremost, these bags are highly durable and can be reused multiple times, which makes them a sustainable option for businesses and consumers alike. Unlike single-use plastic bags, polypropylene bags are built to last, reducing the need for frequent replacements and minimizing waste. Their longevity also translates into cost savings for businesses, as they do not need to continuously purchase new packaging materials.

Another significant benefit is the versatility of polypropylene bags. They can be designed for various uses, from standard shopping bags to specialized packaging for bulk items. Their adaptability makes them suitable for a wide range of industries, including retail, agriculture, and manufacturing. This flexibility allows businesses to utilize a single type of bag for multiple applications, simplifying inventory management and reducing storage space.

Additionally, polypropylene bags are relatively easy to print on, enabling businesses to promote their brand through customized designs. This feature not only enhances the aesthetic appeal of the bags but also serves as a marketing tool. When customers carry branded polypropylene bags, they effectively become walking advertisements, increasing brand visibility and recognition. This integration of functionality with marketing potential makes polypropylene bags an attractive option for both businesses and consumers.

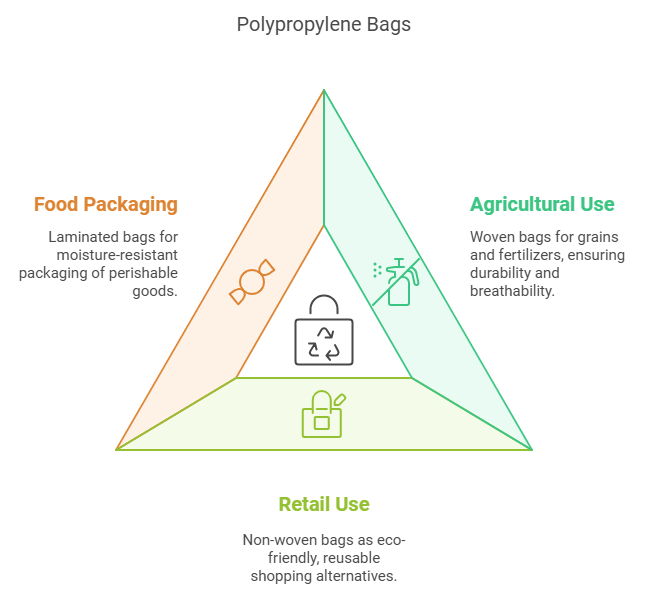

Common Applications of Polypropylene Bags

Polypropylene bags find extensive use across a multitude of industries due to their adaptability and performance. In the agricultural sector, woven polypropylene bags are commonly used for packaging grains, seeds, and fertilizers. Their strength and durability ensure that they can hold heavy loads without tearing, while their breathable nature helps maintain the quality of the contents. Farmers and suppliers prefer these bags for their reliable performance during transport and storage, ultimately contributing to better yields and reduced waste.

In the retail industry, non-woven polypropylene bags have gained immense popularity as eco-friendly shopping bags. As consumers become increasingly conscious of environmental issues, many retailers have shifted to using these bags instead of traditional plastic options. Non-woven bags are not only reusable but also offer a more stylish and durable alternative. They can be easily customized with logos and designs, turning them into effective marketing tools while promoting sustainable practices.

Moreover, laminated polypropylene bags are widely used in the food packaging industry. Their moisture-resistant properties make them an excellent choice for packaging perishable goods such as snacks, frozen foods, and fruits. The ability to print high-quality graphics on these bags also enhances branding opportunities, making them appealing to consumers. These bags help maintain freshness while ensuring that the products are presented attractively on store shelves.

How to Choose the Right Polypropylene Bag for Your Needs

Selecting the right polypropylene bag for your specific needs requires careful consideration of several factors. Firstly, you need to determine the weight and type of contents you plan to package. For heavy items, woven polypropylene bags are ideal due to their superior strength, while non-woven bags are more suitable for lighter products. Understanding the weight and nature of your items will guide you in selecting the appropriate bag type.

Another critical factor to consider is the thickness of the bag. Polypropylene bags come in various thicknesses, measured in microns. Thicker bags generally offer greater durability and resistance to wear and tear, making them suitable for heavier items or products that require extra protection. On the other hand, thinner bags may be sufficient for lighter goods and can be a more cost-effective option.

Additionally, you should evaluate the closure options available for the bags. Polypropylene bags can come with different closure mechanisms, such as zip locks, ties, or heat seals. Depending on your needs, you may want a bag that offers easy access while securely sealing the contents. Considering these factors will help you make an informed decision when choosing the right polypropylene bag for your specific application.

Environmental Impact of Polypropylene Bags

When discussing packaging solutions, the environmental impact is a crucial aspect to consider. Polypropylene bags are often viewed as a more sustainable alternative to traditional plastic bags. They are recyclable and can be repurposed into new products, reducing the amount of waste that ends up in landfills. Many recycling programs accept polypropylene bags, encouraging consumers to engage in responsible disposal practices.

Moreover, the production process of polypropylene bags generally requires less energy compared to other types of plastic bags. This lower energy consumption can lead to reduced greenhouse gas emissions, making polypropylene a more environmentally friendly choice. Additionally, the durability and reusability of these bags mean that they can be used multiple times before needing replacement, further decreasing their overall environmental footprint.

However, it is essential to note that while polypropylene bags are a better option than single-use plastics, they still contribute to plastic pollution if not disposed of properly. Raising awareness about responsible recycling and disposal is vital in maximizing the environmental benefits of polypropylene bags. By promoting sustainable practices, consumers and businesses can work together to minimize the ecological impact of their packaging choices.

Proper Care and Maintenance of Polypropylene Bags

To ensure the longevity and effectiveness of polypropylene bags, proper care and maintenance are essential. First and foremost, it’s crucial to clean the bags regularly, especially if they are used for food packaging or carrying groceries. Most polypropylene bags can be washed with warm water and mild soap. Avoid using harsh chemicals or bleach, as these can damage the material. Allow the bags to air dry completely before storing them to prevent any mold or mildew growth.

Additionally, it is important to avoid overloading polypropylene bags beyond their weight capacity. While these bags are strong, consistently exceeding their limits can lead to wear and tear over time. Following the manufacturer’s guidelines regarding weight capacity will help maintain the integrity of the bags and prolong their usability. If a bag shows signs of damage, such as fraying or tearing, it is best to retire it from use to prevent any spillage or loss of contents.

Storing polypropylene bags properly can also extend their lifespan. Keep them in a cool, dry place away from direct sunlight, as prolonged exposure to UV light can degrade the material. Folding or stacking the bags neatly will help maintain their shape and prevent unnecessary creasing or damage. By following these simple care and maintenance tips, users can maximize the benefits of polypropylene bags and ensure they remain a reliable packaging solution for years to come.

Where to Buy Polypropylene Bags

Finding a reliable source for polypropylene bags is essential for businesses and consumers alike. Many retailers offer polypropylene bags, both in physical stores and online. For bulk purchases, wholesalers and manufacturers are often the best options. They usually provide a wide range of polypropylene bag types, sizes, and customization options, allowing businesses to find the perfect fit for their needs. Websites specializing in packaging supplies can also be a valuable resource for sourcing polypropylene bags.

Local suppliers and manufacturers can be another great option, providing the advantage of quicker shipping times and the ability to inspect the products in person before making a purchase. Many regions have suppliers that specialize in eco-friendly packaging solutions, catering to the growing demand for sustainable products. Engaging with local businesses not only supports the community but can also lead to more personalized service and assistance in choosing the right bags.

Finally, online marketplaces offer a vast selection of polypropylene bags from various sellers, making it easy to compare prices and options. When purchasing online, it’s important to read customer reviews and check the seller’s reputation to ensure you are receiving high-quality products. Whether choosing to buy from a local supplier or an online retailer, the key is to find a source that meets your specific needs while providing excellent quality polypropylene bags.

Conclusion: Why Polypropylene Bags are a Versatile and Sustainable Packaging Solution

In conclusion, polypropylene bags stand out as a versatile and sustainable packaging solution suitable for a myriad of applications. Their unique properties, including strength, moisture resistance, and lightweight design, make them ideal for various industries, from agriculture to retail. The benefits of using these bags extend beyond functionality; they also contribute to brand visibility and cost savings for businesses while promoting eco-friendly practices.

The different types of polypropylene bags available ensure that there is a suitable option for nearly every packaging need. By understanding how to choose the right bag and implementing proper care and maintenance, users can maximize the longevity and effectiveness of their polypropylene bags. Furthermore, recognizing the environmental impact of these bags highlights their role in promoting sustainable packaging alternatives.

As consumers and businesses alike become more conscious of their environmental footprint, polypropylene bags offer an effective way to reduce waste while providing reliable packaging solutions. By embracing polypropylene bags, you not only invest in durability and versatility but also contribute to a more sustainable future. Whether for personal use or business applications, polypropylene bags are indeed a smart choice for modern packaging needs.

Leave A Comment