The increasing awareness of environmental sustainability has prompted significant interest in alternative materials within the textile industry. One such material is PET yarn, which stands for polyethylene terephthalate yarn. This article aims to elucidate the composition, properties, benefits, and applications of PET yarn, particularly focusing on its recycled variants.

What is PET Yarn Made Of?

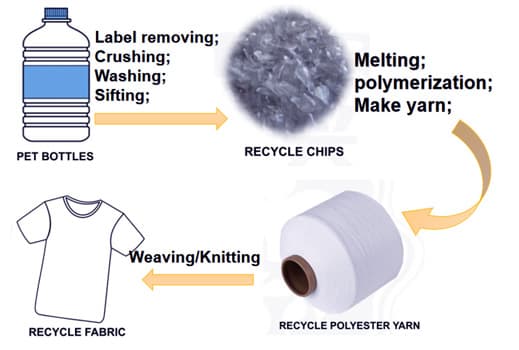

PET yarn is a synthetic fiber derived primarily from recycled plastics, particularly plastic bottles. The production process involves several stages:

- Collection: Used plastic bottles and polyester waste are gathered for recycling.

- Cleaning: The collected materials undergo thorough cleaning to remove contaminants.

- Melting: The purified plastics are heated to a molten state, facilitating the transformation into fibers.

- Spinning: The molten material is extruded through spinnerets, forming long strands of yarn.

- Stretching and Curling: This step enhances the strength and texture of the resulting fibers.

- Packaging: The finished yarn is prepared for distribution to manufacturers.

What is Recycled PET Yarn?

Recycled PET yarn, or rPET, specifically refers to yarn produced from post-consumer plastic waste. This process not only mitigates landfill waste but also conserves resources by reducing reliance on virgin materials. The production of recycled PET yarn is associated with a significantly lower carbon footprint compared to traditional polyester manufacturing, with estimates suggesting reductions of up to 75% in CO2 emissions.

Is PET Yarn Toxic?

A critical aspect of synthetic materials is their safety for consumer use. Research indicates that PET itself is not inherently toxic, and textiles made from recycled plastic bottles are generally deemed safe for wear. However, potential toxicity may arise from dyes and finishing agents used in the manufacturing process. It is imperative for consumers to select products from reputable brands that adhere to safety standards and conduct testing for harmful substances.

Is PET Yarn Soft?

One notable characteristic of pet yarns is their softness. When processed appropriately, recycled PET yarn can achieve a tactile quality comparable to natural fibers such as wool, while also providing enhanced durability and moisture-wicking capabilities. These attributes render it suitable for a variety of textile applications.

What is Pet Yarn Good For?

The versatility of pet yarns allows for a wide array of applications across different sectors:

- Apparel: Clothing items such as t-shirts, jackets, and activewear benefit from the durability and moisture management properties inherent in PET yarn.

- Home Textiles: Products including rugs, curtains, and upholstery made from recycled PET offer both aesthetic appeal and environmental benefits.

- Industrial Uses: Due to its strength and resilience, recycled PET yarn finds utility in industrial fabrics and filtration materials.

Recycle PET Yarn

The principle of recycling extends beyond the initial creation of products; it embodies a circular economy wherein materials are repurposed multiple times. Recycle pet yarn can be reprocessed at the end of its lifecycle, further contributing to waste reduction and resource conservation.

conclusion

In conclusion, an understanding of pet yarn meaning and its associated benefits underscores its significance in advancing sustainability within the textile industry. With attributes such as strength, softness, and eco-friendliness, recycled PET yarn presents an innovative solution to address the challenges posed by plastic waste while providing high-quality textiles for consumers. As global awareness regarding environmental issues continues to grow, the demand for sustainable materials like pet yarn is anticipated to increase, thereby fostering a more sustainable future in fashion and textiles.

wohh precisely what I was looking for, regards for posting.

This is exactly what I wanted to know about PET yarn. A fantastic article!