Polyethylene piping (PE) is a relatively novel concept in today’s piping systems that enjoys widespread acceptance due to its flexibility, toughness, and economy. Used in diverse industries, PE piping offers unparalleled advantages for water supply, gas distribution, and industrial applications. This section delves into the fundamental aspects of PE piping, exploring its properties, types, and sizing standards to provide a comprehensive understanding of its significance.

What is pe pipe?

pe pipe is produced from polyethylene, and the material characteristic that distinguishes it is its flexibility, chemical resistance and it is long-lasting. It is produced from the polymerization of ethylene and then forms long hydrocarbon chains that act as its strength and flexibility.

1. Manufacturing Process

pe pipe is produced using the extrusion method of production. In the pipe extrusion method, polyethylene pellets are melted and forced through a die to produce pipes of various sizes. Finally, the pipes which have passed through the extrusion process, are cooled, sized, and made ready for marketing.

2. Availability

pe pipe is available in two primary forms:

- Straight Lengths: Best used where small projects or installations call for the use of rigid pipes.

- Coils: It should be used in areas where flexibility until long continuous is required such as irrigation practices.

3. Size Variations

These pipes are available in various sizes to fulfill the needs of the client. Standard diameters range from pipes useful for homes to large pipes useful for cities and industries. The size is usually defined in two ways and they are internal diameter (ID) for pipes or outer diameter (OD) for pipes according to the type of PE pipe.

Types of pe pipe

pe pipe is categorized based on its density and specific applications, each offering unique benefits:

1. LDPE stands for Low-Density polyethylene

- Characteristics: HDPE pipe is heavy, rigid, and suitable to operate under high pressure while PE pipe for water, is commonly known as LDPE pipe which is flexible, lightweight, and includes a low-pressure system. They are suitable to install in complicated designs due to their tender nature.

- Applications: Especially in drip and sprinkler systems because the pipes are easy to bend and handle in the course of irrigation.

2. Medium Density Polyethylene (Mid Density Polyethylene or PE80)

- Characteristics: In MDPE pipe, the density is higher and the content is more rigid when compared with LDPE pipe. The elastomers provide reasonable resistance to chemicals and are appropriate for Polyethylene pipe applications with moderate pressure.

- Applications: MDPE pipes are known as Plastic pipes for gas and water and which proved to be efficient and durable.

3. High-density polyethylene (HDPE or PE100)

- Characteristics: Out of all the three types, HDPE pipe is the most resistant to impact, chemicals, and abrasive forces. They are manufactured for use in conditions where there is high pressure.

- Applications: Applied in sewage systems, industrial applications, and high-pressure water supply HDPE pipes are mentioned for their durability and long-lasting properties.

Need reliable HDPE grades for your piping project?

For high-quality HDPE raw materials, including HDPE EX3, HDPE PE80, and HDPE PE100 grades, contact us directly to discuss your specific piping project needs.

pe pipe sizing

Proper sizing is crucial for ensuring the efficiency and safety of PE piping systems. Methods used in pipe sizing vary from one type of pipe to the other and according to the application that is used.

1. Nominal Bore (ID) vs. Outside Diameter (OD) Sizing

- LDPE Pipe: Generally defined by nominal bore ID; nominal bore is an indication of the internal diameter of the pipe.

- MDPE and HDPE Pipe: In nominal size based on outside diameter (OD) and by international practice to allow compatibility with its fittings and jointing systems.

2. Standard Dimensions Ratio Ministers

Standard Dimensional Ratio (SDR) is a key factor in the scalability of PE pipes. This formula determines the ratio of a pipe’s outer diameter to the wall thickness, controlling its pressure-bearing capability.

Key Points About SDR:

Thus, the lower SDR value means a thicker wall, which carries high pressure. Common SDR ratings include:

- SDR11: Used for high-pressure systems.

- 6: Appropriate use on pressure 35-70 psi, Refer to the original equipment manufacturer for correct specifications.

- SDR17: For use in standard-pressure Polyethylene pipe applications.

- SDR21: Perfect when designing low-pressure systems.

Determination of Wall Thickness for the Tunnel and Internal Diameter

Wall thickness and internal diameter are determined using the SDR pipe formula:

For instance, given OD of 160mm and SDR of 11, the thickness of a pe pipe will be about 14.5 mm. This is why the calculations are important to making sure a pipe provides sufficient pressure and has enough endurance for a project.

PE piping has transformed how industries approach piping systems, offering a durable, efficient, and cost-effective alternative to traditional materials. With knowledge concerning the properties, types, and methods for sizing PE pipes, users can select the most appropriate one that meets the requirements of every application and has the most continuous usage.

PE pressure ratings

The PE pressure ratings are critical specifications for pe pipes, representing the maximum operating pressure the pipe can handle under standard conditions. Given in bars, where 1 bar is equal to 100 kPa, PN rating is one more criterion that denotes the application of pipes. For instance, PN10 shows that it has the resistance to withstand 10 bar pressure during its normal working conditions.

The PN pipe rating is directly associated with its wall thickness and Standard Dimensional Ratio or SDR. The pipes with low SDR values contain more wall thickness and thus can carry high pressure. For instance, a PE pipe with PN16 typically corresponds to SDR11, while PN10 aligns with SDR17. This relationship ensures a balance between the pipe’s structural needs and flexibility to meet different ranges of pressures.

Temperature significantly influences the pressure capabilities of PE pipe. Additionally, the material loses its strength at elevated temperatures therefore its pressure rating decreases. On the other hand, at lower temperatures, the usable pressure of the pipe may increase. It is because engineers have to take into account the variability of the temperatures during their designing process to guarantee that the pipe will work fine in the area that is expected to function in.

PE pipe fittings and jointing methods

pe pipes offer a range of fitting and jointing options to suit diverse applications and pipe types. Barbed PE pipe fittings are used for Low-Density Polyethylene (LDPE) connections that may be clipped or have cap nuts for creating secure connections in low-pressure systems like irrigation. MDPE and HDPE pipe, are used to provide enhanced facilities, use mechanical compression fitting, installation techniques that are easy to execute, and non-huge tools are needed.

In particular, the systems made of MDPE and HDPE require stronger and leak-proof PE pipe connectors and for this reason, electrofusion fittings and butt fusion jointing are used. Electrofusion refers to the process of heating some components fitted within the fitting to weld the pipe ends tightly. Unlike other techniques, butt fusion binds the pipe ends through heat to form a direct pipe pipeline that offers high pressure and continuity. These ensure the best and long-run ways of ensuring that PE piping systems conform with the best industrial standards.

Properties and advantages of pe pipe

pe pipes are renowned for their exceptional properties and the numerous advantages they bring to piping systems, making them a preferred choice across industries.

- Lightweight and Flexible: One of the defining features of PE pipes is their lightweight nature. Compared to traditional materials like steel or concrete, PE pipes are significantly lighter, simplifying transportation and installation.

- Chemical Resistance and Inertness: pe pipes are chemically inert, meaning they are resistant to a wide range of substances, including acids, alkalis, and solvents. This property makes them suitable for applications where they can be exposed to corrosive material such as industries and chemical transportation.

- Toughness and Longevity: With a lifespan exceeding 100 years under normal operating conditions, PE pipes are designed for durability. They can therefore absorb impacts, and high pressures and can withstand harmful environmental conditions.

- UV Resistance: Ultraviolet (UV) radiation does not have any effect on PE pipes because they are used outdoors. This resistance assists in protecting against breakdown due to light exposure, an issue that is common with most plastics.

- Reduced Installation Costs: The flexibility and lightweight nature of PE pipes contribute to significantly reduced installation costs. These pipes can be completed with the use of trenchless construction that reduces the invasion of soil and the environment of infrastructure.

- Recyclability: PE pipes are fully recyclable, aligning with global efforts toward sustainability and environmental conservation. After these pipes have fulfilled their expected usage, they can be reused for other products which will not only standardize the usage of pipes but also curb the usage of raw materials in making the pipes.

- Cost-Effectiveness: Compared to metallic piping systems, PE pipes offer a more economical solution. Because they have smaller first costs along with lesser operating and installation costs, FBP has become efficient for small to large pipe fabricating projects.

Applications of pe pipe (What is PE pipe used for)

The versatility of pe pipes allows them to cater to a wide range of applications across various sectors:

- Potable Water Supply and Distribution: PE pipes are widely used for drinking water systems due to their inert nature, ensuring water remains uncontaminated.

- Natural Gas Distribution: PE pipes have good leakage and corrosion characteristics making it possible to use in transporting natural gas.

- Sewer and Drainage Systems: PE pipes can handle high flow rates and resist harsh chemicals, making them suitable for sewer and drainage infrastructure.

- Irrigation Systems: From agricultural irrigation to garden sprinklers, PE pipes provide efficient water delivery solutions.

- Lawn Sprinklers: Lightweight and flexible, PE pipes are easy to install in residential lawn sprinkler systems.

- Radiant Floor Heating: With reference to hydronic heating systems the global pe pipes are employed in laying heat across floors.

- Geothermal Ground Source Heat Pump Piping: Their excellent thermal conductivity and resistance to chemicals make PE pipes an ideal choice for geothermal systems and Underground piping.

- Industrial Applications: PE pipes are employed in transporting chemicals, wastewater, and other industrial materials due to their robustness and chemical resistance.

Choosing the right pe pipe for your project

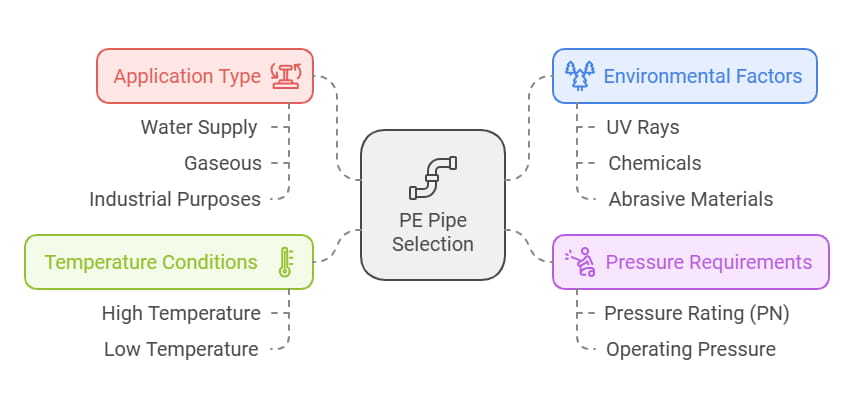

Selecting the appropriate pe pipe requires careful consideration of several factors:

- Application Type: Determine the precise use of the Plastic pipe for water supply, gaseous, or industrial purposes.

- Pressure Requirements: It also recommends an optimal pressure rating (PN) that should be suited to the operating pressure of the system.

- Temperature Conditions: Think also, about the extent of temperature exposed to the pipe since pipes operating at high or low temperatures might not function optimally.

- Environmental Factors: Consider visibility to UV rays, chemicals, and abrasive materials when selecting a pipe.

Conclusion

pe pipes have transformed the piping industry with their exceptional properties, versatility, and cost-effectiveness. For use in potable water, and other purposes such as industrial usage, they provide incomparable benefits of high durability, chemical point resilience, and friendly environmental impact. As industries continue to seek reliable and eco-friendly solutions, PE pipes remain at the forefront, ensuring efficient and sustainable infrastructure for generations to come.

Leave A Comment