Imagine holding a LEGO brick or sipping water from a lightweight, transparent bottle. These everyday objects share a remarkable secret: they’re made from thermoplastics, a remarkable class of materials that have quietly revolutionized our world. From the smartphone in your hand to the car parts that keep you safe, thermoplastics are everywhere, yet most of us know very little about thermoplastic. So, what is thermoplastic? And what makes them so special? This article will provide a comprehensive guide, answering key questions like “what is a thermoplastic?” and “what are thermoplastics used for?”.

What Are Thermoplastics? Thermoplastics Definition

At their core, thermoplastics are a unique type of plastic with an extraordinary ability: they can be heated, shaped, and reshaped multiple times without losing their fundamental properties. Unlike other materials that break down or permanently change when exposed to heat, thermoplastic polymers can transform like magical substances. When heated, they soften and become malleable; when cooled, they return to a solid state, retaining their strength and integrity. This defines a thermoplastic material.

The phrase “thermoplastic is” often refers to this key property of being “thermo-pliable.” This remarkable characteristic makes thermoplastics not just versatile but also environmentally promising. They can be recycled, reused, and reshaped, offering a potential solution to some of our most pressing environmental challenges. For a simple understanding, “themoplastic” or “thermoplastik” are just common misspellings for these incredibly useful materials.

Thermoplastics vs. Thermosets: Understanding the Difference

To truly appreciate thermoplastics, it’s essential to understand how they differ from other types of plastics, particularly thermosets. The fundamental difference between thermoplastics and thermosetting plastics lies in their behavior when exposed to heat:

- Thermoplastics: Can be repeatedly melted and remolded without significant chemical changes.

- Thermosets: Harden permanently after initial heating, becoming rigid and unable to be reshaped.

Think of thermo plastics as clay that can be molded repeatedly, while thermosets are more like concrete—once set, they cannot be changed. This is the key distinction in the thermoplastic vs thermosetting polymer debate.

This table highlights the core thermoplastic characteristics that set them apart from thermosets.

The Molecular Magic: How Thermoplastics Work

The secret to thermoplastics lies in their thermoplastic molecular structure. These materials are composed of long, linear, or slightly branched molecular chains that are held together by weak intermolecular forces. This unique thermoplastic structure allows them to slide past each other when heated, causing the material to soften and become pliable without breaking down chemically. This is the core science behind what a thermoplastic polymer truly is.

Thermoplastics can exist in two primary structural arrangements, influencing their final properties:

- Crystalline: Molecules are tightly organized, resulting in more opaque, stronger, and less flexible materials (e.g., HDPE).

- Amorphous: Molecules are more randomly arranged, creating clearer, more flexible materials (e.g., LDPE).

Manufacturers can further modify themoplastics by adding various additives like plasticizers (to increase flexibility), stabilizers (to prevent degradation), and colorants. These modifications allow for an incredible range of properties and applications, as seen in countless thermoplastic parts.

From Granules to Products: The Making of Thermoplastics

The journey of a thermoplastic product begins with raw materials. The answer to “what is thermoplastic made of?” is typically petroleum, though bio-based alternatives are gaining ground. The process of “how are thermoplastics made?” involves several key steps:

- Granule Production: Raw materials are processed into small, uniform pellets or granules.

- Additive Incorporation: Specialized additives are mixed to achieve desired properties for specific uses of thermoplastic.

- Molding Techniques: The granules are then transformed into products using various methods:

- Extrusion: Pushing material through a die to create long, uniform shapes like pipes, sheets, or profiles. This is a common method for making thermoplastic

- Injection Molding: Melting granules and injecting them into precise molds to create complex, high-volume thermoplastic objects.

- Thermoforming: Heating a plastic sheet and shaping it over a mold, as seen in packaging and trays.

- Blow Molding: Used to make hollow thermoplastic objects like bottles and containers.

This diverse range of manufacturing techniques makes thermoplastics highly adaptable for various products in thermoplastics.

The Thermoplastic Family: Diverse and Versatile

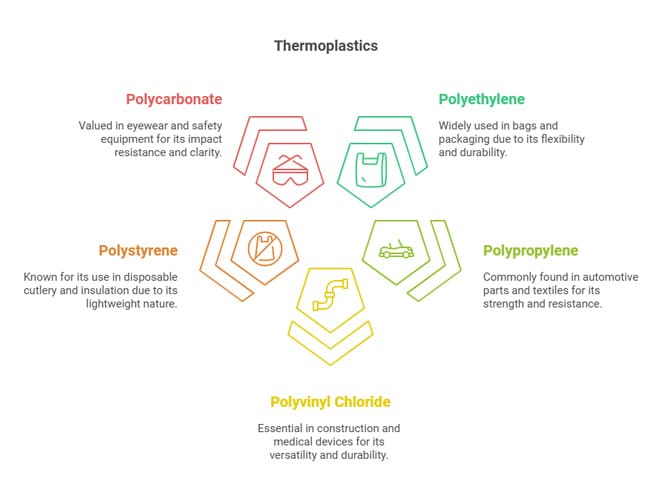

Several thermoplastics dominate the market, each with unique characteristics:

A wide array of thermoplastic types dominate the market, each with unique characteristics that make them suitable for specific uses. Here are some of the most prominent thermoplastics examples:

- Polyethylene (PE): Found everywhere from plastic bags to bottles and durable piping. A key member of the thermoplastic family.

- Polypropylene (PP): Common in automotive parts, flexible hinges, and durable packaging.

- Polyvinyl Chloride (PVC): Found in construction materials, pipes, and medical devices.

- Polystyrene (PS): Used in disposable cutlery, packaging, and insulation.

- Polycarbonate (PC): Known for its use in eyewear, electronic components, and safety equipment due to its impact resistance.

- Polyester (PET): The plastic used in beverage bottles and textiles.

These examples of thermoplastics are an integral part of our modern world, and the names of thermoplastics listed here only scratch the surface of this versatile family.

Advantages and Disadvantages of Using Thermoplastics

The use of thermoplastic materials comes with a clear set of pros and cons, which helps in the selection process.

Pros (Advantages):

- Highly Recyclable: Can be repeatedly melted and reprocessed, supporting a circular economy. This is a major reason for the increasing uses of thermoplastics.

- Versatile and Adaptable: Can be easily formed into a wide variety of shapes, from flexible films to rigid thermoplastic parts.

- Cost-Effective: Generally inexpensive to produce and process into final products.

- Lightweight: Thermoplastic parts offer excellent strength-to-weight ratios.

- Chemical Resistance: Resistant to many chemicals, acids, and bases.

- Wide Range of Properties: The variety of thermoplastic types allows for a broad range of physical and mechanical properties.

Cons (Disadvantages):

- Lower Melting Point: They soften at lower temperatures compared to thermosets, which can be a limitation for high-heat applications.

- Potential for Creep: Gradual deformation under constant stress can occur over time.

- Susceptibility to UV Degradation: Some types can degrade when exposed to sunlight, requiring stabilization.

- Recycling Challenges: While recyclable, effective recycling of all thermoplastic types requires robust infrastructure.Understanding these “facts about thermoplastics” is crucial for effective material selection.

Thermoplastics and the Environment: A Look at Sustainability

Thermoplastics present both opportunities and challenges for sustainability. Their inherent recyclability is a significant advantage, potentially supporting a circular economy. The use of packaging thermoplastics in particular is a key area for recycling efforts. However, effective recycling requires robust infrastructure and consumer awareness. The future looks promising with the development of bio-based thermoplastics like Polylactic Acid (PLA), which are derived from renewable resources and offer a reduced environmental impact.

Conclusion

Thermoplastics are more than just a material—they’re a testament to human innovation. From medical devices to sustainable packaging, from automotive components to everyday consumer goods, these remarkable substances continue to transform how we live, work, and interact with our environment. The definition of thermoplastics as re-moldable polymers is the key to their immense utility.

As we move forward, the key will be balancing the incredible utility of thermoplastics with responsible production, use, and recycling. By understanding these materials, including the difference between thermoplastics and thermosetting plastics, we can make more informed choices and contribute to a more sustainable future. The answer to “what is thermoplastic used for?” is truly “almost everything.”

Leave A Comment