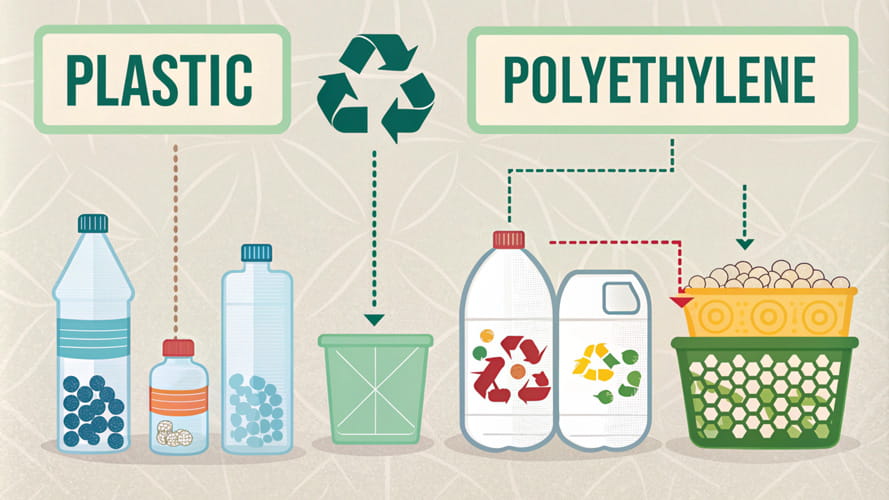

Quick Answer: Yes, polyethylene is a plastic. In fact, it is the most common and widely produced form of plastic used in the world today. While “plastic” is the broad, overarching category for malleable synthetic materials, polyethylene (PE) is a specific, distinct type within that extensive family.

In the vast landscape of the materials industry, terminology can be a significant barrier. Confusion often arises regarding specific names versus general categories. Questions like “what is the difference between plastic and polythene” or “is poly plastic?” are frequently asked by consumers and business owners alike. This guide aims to demystify these terms, clarifying the relationship between the broad universe of plastics and the specific, ubiquitous polymer known as polyethylene.

The Core Relationship: Polyethylene vs. Plastic

To truly understand the polyethylene vs plastic comparison, it is helpful to use a simple analogy: think of it as the relationship between “cars” and “Toyotas.”

- Plastic is the broad category (the Vehicle). This includes thousands of different materials with varying properties, such as PVC, Nylon, Polyester, and Acrylic.

- Polyethylene is a specific make/model (the Toyota). It is one specific member of the plastic family with its own unique “engine” (chemical structure) and “performance stats” (physical properties).

Therefore, asking “is polyethylene a type of plastic?” is exactly like asking if a Toyota is a type of car. The answer is definitively yes. PE plastic belongs to a massive family of synthetic materials, but it stands out as the industry leader due to its specific chemical structure, ease of processing, and widespread utility in everything from food wrap to bulletproof vests.

| Comparative Aspect | Plastic | Polyethylene |

|---|---|---|

| Conceptual Definition | Expansive material category of synthetic polymers. | A specialized plastic subset; a specific type of polymer. |

| Molecular Composition | Diverse polymer sources and chemical compositions. | Exclusively ethylene-derived polymer. |

| Structural Flexibility | Widely variable across different plastic types. | Consistently predictable (e.g., LDPE is flexible, HDPE is rigid). |

| Primary Applications | Multidisciplinary, from construction to electronics. | Primarily packaging, films, containers, and piping. |

| Scope | The general term. | A specific example within that general term |

Polythene vs. Polyethylene: What’s the Difference?

Before diving deeper into the science, let’s address a common linguistic hurdle that causes confusion across borders: polythene vs polyethylene.

- They are exactly the same material. There is no chemical difference between them.

- “Polyethylene” is the standard scientific IUPAC name used globally and predominantly in the US manufacturing sector.

- “Polythene” is the common trade name or shortening, widely used in the UK, India, and other Commonwealth regions.

So, when you are comparing plastic and polythene, you are simply comparing the general material category to its most popular specific member. It is merely a difference in dialect, not chemistry.

What Type of Plastic is Polyethylene?

Now that we have established that it is a plastic, what kind of plastic is polyethylene exactly?

Scientifically, polyethylene is classified as a thermoplastic polymer. This classification is crucial for manufacturers and recyclers. unlike thermoset plastics, which form irreversible chemical bonds when cured (think of epoxy glue or a rubber tire that burns if reheated), thermoplastics like polyethylene become liquid (pliable) at their melting point and solidify when cooled. This allows them to be remolded and recycled multiple times—a key difference between polythene and plastic variants that are thermosets.

It falls under the family of polyolefins and is derived from the polymerization of ethylene gas. Depending on how the ethylene molecules bond during manufacturing—specifically, how much “branching” occurs in the molecular chain—it takes on different forms:

- LDPE (Low-Density Polyethylene): The molecular chains in LDPE have many branches, preventing them from packing tightly together. This results in a material that is flexible, soft, and transparent (e.g., shopping bags, bubble wrap).

- HDPE (High-Density Polyethylene): These molecular chains are linear with very little branching, allowing them to pack tightly into a dense, strong structure. This makes HDPE rigid, tough, and usually opaque (e.g., milk jugs, detergent bottles, water pipes).

- LLDPE (Linear Low-Density Polyethylene): This variant combines the toughness of HDPE with the flexibility of LDPE. It is engineered to have high tensile strength and puncture resistance (e.g., stretch films, agricultural covers).

Is Polyethylene “Better” Than Plastic?

A frequent question is: “is polyethylene better than plastic?”

This question is slightly misleading because polyethylene is plastic. However, if we interpret this as “is polyethylene better than other types of plastics,” the answer depends entirely on the application:

- Durability and Resistance: PE offers superior chemical resistance compared to plastics like Polystyrene (PS). It does not degrade easily when exposed to acids or bases, making it ideal for chemical tanks.

- Safety and Toxicity: Polyethylene plastic is often preferred for food storage over plastics like PVC (Polyvinyl Chloride). PE is chemically inert and typically does not contain Bisphenol A (BPA) or phthalates, making it a safer choice for food containers and water bottles.

- Cost and Efficiency: It is generally more affordable and energy-efficient to produce than specialized engineering plastics like Polycarbonate or PEEK. Its lower melting point also means it requires less energy to mold.

Conclusion

Ultimately, the distinction between “plastic” and “polyethylene” is one of scope. While plastic represents the broad category of synthetic materials, polyethylene stands out as its most vital and versatile member. Whether you call it “poly,” “polythene,” or “PE,” understanding its specific properties—from the flexibility of LDPE to the strength of HDPE—empowers better decision-making in manufacturing and recycling. As the world moves toward more sustainable practices, recognizing polyethylene’s unique potential for reuse and recycling helps distinguish it from less eco-friendly plastics, ensuring it remains a cornerstone of modern material science.

Summary: Key Takeaways

- Is polyethylene a plastic? Yes, it is the world’s most widely used thermoplastic, known for its versatility.

- What is polyethylene plastic? It is a synthetic resin made from the polymerization of ethylene, available in varying densities (LDPE, HDPE).

- Is polyethene a plastic? Yes, “polyethene” (or polythene) is just another regional name for polyethylene; the material is identical.

Frequently Asked Questions: Plastic vs Polyethylene

- Is polyethylene a plastic or rubber?

Polyethylene is a plastic. While some forms (like LDPE) are flexible and might feel somewhat rubbery, they are chemically distinct from rubber (elastomers). Rubber is typically a thermoset that cannot be melted and reshaped, whereas polyethylene is a thermoplastic.

- What is the difference between polythene and plastic?

“Plastic” is the umbrella term for the entire group of synthetic malleable materials. “Polythene” is a specific type of plastic (polyethylene) known for its chemical resistance, waxy feel, and hydrophobic nature.

- Is poly plastic recyclable?

Yes, most PE plastics are highly recyclable. HDPE (#2) and LDPE (#4) are staples of municipal recycling programs because they can be melted down and reformed into new products like lumber, trash bins, and floor tiles without losing significant structural integrity.

- Why do people say “Plastic and Polythene” separately?

This is often a colloquial habit. In many regions, “polythene” became synonymous with plastic bags specifically (e.g., “a polythene bag”), leading people to treat them as separate terms in conversation, even though technically polyethylene is plastic.

Leave A Comment