On a packaging line, the difference between “good enough” film and reliable film shows up fast: a torn corner on a pallet, a pinhole that leaks, a bag seam that opens in transit. That’s why linear low density polyethylene (LLDPE) matters. It delivers toughness and stretch in thin gauges, making down-gauging realistic without turning production into a gamble.

LLDPE polyethylene also appears well beyond packaging—in agricultural films, geomembranes, hoses, cable jacketing, and many rugged molded parts. Small shifts in LLDPE density, melt flow, comonomer type, and additives can change how it runs and how the finished product behaves.

Shobeir Shimi has been active in polymer trade since 2003. In practice, buyers don’t only need volume; they need the right LLDPE material with repeatable specs, clear documentation, and logistics that protect the resin from origin to destination.

What is Linear Low-Density Polyethylene (LLDPE)?

If you’re asking “what is LLDPE?” the short answer is: a flexible polyethylene designed to be stronger than LDPE in many film and flexible applications. Technically, linear low-density polyethylene is an ethylene copolymer made under low-pressure polymerization, commonly with alpha-olefins such as butene (C4), hexene (C6), or octene (C8).

Compared with LDPE, LLDPE plastic often provides higher tensile strength and better puncture resistance—why it’s widely used in stretch film and heavy-duty bags. Compared with HDPE, it stays more elastic, which helps when products must bend and absorb impact.

Definition of LLDPE Polymer and Its Characteristics

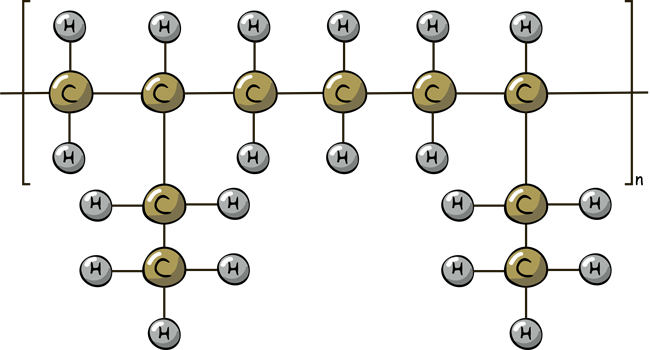

From a material science point of view, LLDPE polymer is “linear” because it has a mostly straight backbone with lots of controlled short branches (rather than random long-chain branching). Those short branches change how molecules pack and slide—creating a balance of toughness and flexibility that’s hard to beat.

Common LLDPE characteristics that buyers care about include:

- High elongation (stretches without snapping)

- Good tear and puncture resistance

- Strong chemical resistance in many environments

- Reliable performance across many converting and molding methods

This is why linear low-density polyethylene material is often selected when you want a film or part that can take abuse without becoming brittle.

The Evolution of Linear Polyethylene

Historically, high-pressure LDPE was everywhere because it processed easily and could look very clear in film. But as packaging demanded more strength at lower thickness—and as converters pushed higher line speeds—linear polyethylene grades became the smarter option. Today, LLDPE is widely traded and produced across major petrochemical hubs, and improvements in supply networks have made it a global commodity for both local and export markets.

Chemical Structure and LLDPE Grades

One of the fastest ways to understand grade behavior is to connect chemistry to performance.

Understanding the LLDPE Structure vs. LDPE

The LLDPE structure is mainly linear with uniform short branches. LDPE contains more long and irregular branching, which often improves clarity and melt behavior, while LLDPE typically improves toughness and puncture resistance. This is why blends are common in film: LDPE supports optics and runnability; LLDPE carries the mechanical load.

Comonomers Used in LLDPE Resin (Butene, Hexene, Octene)

- C4 (butene) LLDPE resin is widely used and cost-effective for many general films.

- C6 (hexene) grades are often chosen for improved toughness and puncture resistance.

- C8 (octene) grades are used when higher mechanical performance is needed (grade-dependent).

Some suppliers also offer metallocene LLDPE (MLLDPE) for tighter consistency and strong sealing behavior. You may also see “linear low-density polyethylene LLDPE” written in RFQs—usually just the same family with the acronym repeated for clarity.

LLDPE Granules And Grades

| GRADE | PRODUCER | MFR | DENSITY | DATASHEET |

|---|---|---|---|---|

| 18B01 | BAKHTAR | 0.8-1.2 | 0.916 – 0.920 | |

| 22B02 | BAKHTAR | 0.4-0.6 | 0.920 – 0.924 | |

| 0220KJ | AMIRKABIR | 2.4 | 0.921 | |

| 0220AA | AMIRKABIR, SHAZAND | 2.2 | 0.920 | |

| LL 235F6 | JAM | 0.5 – 0.7 | 0.920 – 0.924 | |

| LL235F7 | JAM | 0.7 | 0.922 – 0.925 | |

| 22501AA / 22501KJ | JAM | 0.95 | 0.9220 | |

| 22502AA | JAM | 1.80 | 0.922 | |

| 32604 | JAM | 4 | 0.932 | |

| 18B03 | BAKHTAR | 2.8-3.2 | 0.916-0.920 | |

| 18B04 | BAKHTAR | 4-5 | 0.915-0.918 | |

| 22B01 | BAKHTAR | 0.8-1.2 | 0.920-0.924 | |

| 22B03 | BAKHTAR | 2.8-3.2 | 0.920-0.923 | |

| 22B01 KJ | BAKHTAR | 1±0.2 | 0.922±0.002 | |

| 22B02 KJ | BAKHTAR | 2±0.2 | 0.922±0.002 | |

| 20BF5 | BAKHTAR | 0.5±0.1 | 0.920±0.002 | |

| 22501AA | JAM | 0.95 | 0.922 | |

| 0209AA | Amir Kabir | 0.9 | 0.920 |

LLDPE Granules, Industrial and Export-Grade

Shobeir Shimi LLDPE granules are developed to be trusted in the packaging, film, pipe, cable, and rotational molding duties. The LLDPE that we obtain is of superior quality in the market in order to maintain steadiness in the quality, consistency in the processing of the product, and high mechanical strength at each batch. We offer numerous LLDPE grades that are applicable in:

- Movie extrusion of stretch film, agricultural film, liners, and packaging.

- Irrigation, water handling, and industrial flow line pipe and hose extrusion.

- Tanks, containers and large hollow parts and rotation molding.

- Where the performance of wire and cable jacketing is dependent on flexibility and insulation.

LLDPE materials are offered in all:

- Big and small bulk orders.

- 25 kg and jumbo bags are some of the several packing choices.

- Extensive technical documentation and quality reports on request.

LLDPE Supplier and Exporter Worldwide

Shobeir Shimi assists its customers in the local and global markets in the quick processing of orders and export legalization. Our logistics department utilizes shipments using the most critical ports in the Middle East to ensure timely delivery at the most affordable costs.

Reasons to select our LLDPE Materials

Here are reasons to choose us in Shobeir Shimi:

- Consistent quality and repeatability of the linear low-quality processing behavior of all grades.

- Technical service to assist in choosing the appropriate LLDPE grade of film, pipe or molding and cable.

- Project-based and ongoing supply contracts that are flexible.

Documentation and Certifications of LLDPE

To maintain the safe use and export/import, we will supply all documents on each shipment of LLDPE. Our customers are able to order full, updated files of every grade that they buy. Documentation is available in the form of:

- Technical Data Sheet (TDS) having essential physical, mechanical, and processing characteristics.

- Handling, storage and safety guidelines as contained in the Safety Data Sheet (SDS/MSDS).

- Each batch will be issued with a Certificate of Analysis (COA) indicating that the product is as stated in the agreed terms.

- Export shipment packing list, invoice and Certificate of Origin when necessary by the customs or the buyer.

All the papers are drafted in plain English and can be sent electronically before loading. Our team is also able to match documentation to particular regulatory or customer requirements of food-contact, packaging, pipe, cable, or other use on request.

Where to Buy LLDPE

In the sourcing of linear low density polyethylene, the quality, traceability and reliability are the most important. Shobeir Shimi Company is one of the main suppliers and distributors of LLDPE grades in Iran and other countries that offer high quality polymers of major manufacturers such as JAM, Bakhtar, Amir Kabir and Shazand. The grades that we have are:

LLDPE 32604, 22502AA, LL235F6, 0220AA, LL18B01, 22B02KJ, 18B04, and the list is extensive, each of them has a comprehensive technical datasheet. Companies can also collaborate with Shobeir Shimi to acquire uniform quality, which is competitive.

Ready to Purchase LLDPE Granules or Resin?

When you need a supplier of Linear Low-Density Polyethylene that you can rely on to provide quality products in time, Shobeir Shimi is willing to offer its services to your business. We will assist you in selecting the appropriate grade of LLDPE in film, pipe, cable, or molding projects, as well as budgeting a safe supply of local production and export projects.

Call Shobeir Shimi now to talk over your LLDPE needs personally, to ask us to provide current prices, and to give you the technical information on those grades that best suit your process.

Key Properties of Linear Low-Density Polyethylene

When engineers search linear low density polyethylene properties or LLDPE properties, they are typically aligning material performance with a specific processing method or end-use requirement. LLDPE is engineered with a linear backbone and controlled short-chain branching, which gives it a unique balance of strength, flexibility, and durability.

One of the defining characteristics of linear low density polyethylene (LLDPE) is its excellent tensile strength combined with high elongation at break. Unlike conventional LDPE, LLDPE can stretch significantly under load while maintaining structural integrity. This makes it ideal for applications that require impact resistance and load retention, such as:

- Stretch films and pallet wrap

- Agricultural films and greenhouse covers

- Heavy-duty sacks and liners

- Industrial packaging films

- Geomembranes

Another critical advantage of LLDPE material is its outstanding resistance to tear propagation. While some polymers may resist initial puncture but fail once a tear starts, LLDPE resists tear growth effectively — a key requirement in demanding packaging and containment applications.

LLDPE also provides:

- Strong puncture resistance

- Excellent environmental stress crack resistance (ESCR)

- Good chemical resistance to acids, bases, and many solvents

- Reliable sealability in film applications

- Good processability in blown and cast film extrusion

Because of these properties, LLDPE plastic has become the preferred material for flexible packaging where performance-to-cost ratio matters.

Density of LLDPE and Its Impact on Performance

The density of LLDPE typically falls in the range of approximately 0.910 to 0.940 g/cm³, depending on comonomer type and grade design. Even small shifts in density can significantly influence mechanical behavior.

- Lower density LLDPE (≈0.910–0.920 g/cm³)

- Softer feel

- Greater flexibility

- Higher elongation

- Improved impact resistance

- Higher density within the LLDPE range (≈0.930–0.940 g/cm³)

- Increased stiffness

- Higher tensile strength

- Improved load-bearing performance

- Better dimensional stability

While density is often used as a first screening parameter, it should never be evaluated alone. Engineers must consider it alongside:

- MFR / MFI (Melt Flow Rate / Melt Flow Index)

- Tensile strength and elongation targets

- Dart impact and tear resistance

- Processing method (blown film, cast film, injection, rotational molding)

For export buyers and converters, selecting the correct LLDPE density ensures optimal balance between downgauging potential and mechanical reliability.

Thermal Properties: LLDPE Melting Point

The linear low density polyethylene melting point generally falls in the range of 120–125°C, though exact values depend on grade and comonomer structure.

However, processing temperatures are significantly higher than the melting point. In blown film extrusion, for example, melt temperatures often range between 170–220°C, depending on screw design, output rate, and formulation.

Key thermal characteristics of LLDPE include:

- Moderate crystallinity compared to HDPE

- Good heat seal performance

- Stable thermal behavior under typical extrusion conditions

- Suitable for applications requiring flexibility at low temperatures

LLDPE maintains flexibility even in cold environments, which makes it especially valuable in stretch films and agricultural films exposed to varying climates.

Understanding the relationship between LLDPE melting point, processing temperature, and crystallinity helps converters optimize cycle time, energy use, and final product performance.

Production and Processing of LLDPE

Understanding how linear low density polyethylene (LLDPE) is produced helps buyers and converters better interpret performance differences between grades. The molecular structure created during polymerization directly influences density, melt flow rate (MFR), mechanical strength, and film behavior.

Polymerization: How LLDPE Material is Made

LLDPE material is produced through the copolymerization of ethylene with alpha-olefins, most commonly:

- Butene (C4)

- Hexene (C6)

- Octene (C8)

These comonomers introduce controlled short-chain branching into the polyethylene backbone. Unlike LDPE, which has long-chain branching from high-pressure free-radical polymerization, LLDPE is manufactured using low-pressure catalytic processes, typically with:

- Ziegler–Natta catalysts

- Metallocene catalysts (for advanced performance grades)

The choice of comonomer and catalyst system determines:

- Density range

- Mechanical strength

- Impact resistance

- Optical clarity

- Processability

For example:

- Butene-based LLDPE is widely used and cost-efficient.

- Hexene or octene-based LLDPE generally provides improved toughness and puncture resistance, especially in high-performance stretch films.

This controlled molecular architecture is what gives linear low density polyethylene its superior balance of strength and flexibility compared to conventional LDPE.

Industrial Production Technologies

LLDPE is typically produced using one of the following industrial reactor technologies:

- Gas-phase fluidized bed reactors

- Slurry loop reactors

- Solution polymerization processes

Each production method affects molecular weight distribution and final resin characteristics.

Gas-phase technology is particularly common due to its energy efficiency and ability to produce a wide range of LLDPE grades suitable for film, injection molding, and rotational molding applications.

Processing Methods of LLDPE Plastic

After polymerization, LLDPE resin is pelletized and supplied to converters. The material is known for its excellent processability across multiple fabrication methods:

1. Blown Film Extrusion

The most common application. LLDPE offers:

- High bubble stability

- Strong melt strength

- Excellent film toughness

- Downgauging capability

2. Cast Film Extrusion

Used for stretch films and cling films where clarity and uniform thickness are critical.

3. Injection Molding

Suitable for lids, containers, and flexible molded parts.

4. Rotational Molding

Used for tanks, large hollow parts, and industrial containers.

Processing temperatures generally range between 170°C and 220°C, depending on grade and application. Proper control of melt temperature, cooling rate, and shear conditions ensures optimal mechanical properties and surface finish.

Why Production Method Matters for Buyers

For export customers and converters, understanding how LLDPE material is manufactured helps in:

- Selecting the right grade for film strength targets

- Optimizing line speed and energy consumption

- Achieving consistent sealing performance

- Ensuring reliable mechanical performance in final products

Different production technologies and catalyst systems can result in noticeable differences in performance — even when density and MFI appear similar on paper.

Major LLDPE Uses and Applications

The applications of low density LLDPE polyethylene in various industries are many. The polymer is appreciated for its strength, chemical resistance, as well as flexibility, which allow it to be used in:

1. Plastic films and sheets

LLDPE is a superstar in the production of plastic films, sheets, and wraps. Its flexibility and strength make it the go-to material for various packaging solutions like plastic bags, stretch films, shrink films, and liners. Whether it’s protecting goods during shipping or keeping food fresh, LLDPE’s ability to form thin, durable layers ensures it meets the demands of modern packaging. Thanks to its tensile strength and resistance to tearing, industries rely on this material to create reliable and cost-effective packaging options.

2. Plastic pipes

Looking for a material that can handle tough jobs like water and gas distribution? LLDPE shines in the manufacturing of plastic pipes. Its outstanding chemical resistance and durability make it perfect for applications such as sewage systems, irrigation lines, and chemical transfer pipes. With a structure that withstands pressure and environmental stress, LLDPE pipes offer a long-lasting solution for fluid transport in both residential and industrial settings.

3. Plastic Bottles And Containers

LLDPE is employed in crafting bottles and containers for everyday liquids like detergents, shampoos, and household cleaners. Its flexibility allows it to be molded into various shapes, while its excellent moisture barrier properties keep contents safe and secure. Next time you reach for your shampoo or dish soap, chances are LLDPE is playing a key role in keeping it contained and protected! This material’s lightweight nature also makes it a practical choice for manufacturers and consumers alike.

4. Geomembranes

When it comes to large-scale waterproofing and lining projects, LLDPE steps up as the material of choice for geomembranes. These large plastic sheets are essential in construction, landfills, and environmental applications, preventing leaks and protecting the environment. With a density range of 0.910 to 0.940 g/cm³ and high resistance to chemical damage, LLDPE geomembranes ensure durability and reliability in even the toughest conditions.

5. Wire And Cable Insulation

LLDPE’s excellent electrical insulation properties make it a standout option for insulating wires and cables in the electrical and telecommunications industries. Its ability to resist moisture and maintain structural integrity under varying temperatures ensures safe and efficient performance. From power lines to communication cables, LLDPE provides a protective layer that keeps everything running smoothly.

6. Toys And Household Items

LLDPE’s toughness, flexibility, and chemical resistance make it a popular pick for manufacturing toys, kitchenware, and other household items. Whether it’s a durable toy for kids or a reliable storage container in your kitchen, this material delivers safety and longevity. Its ability to withstand impact and resist cracking ensures these products can handle the wear and tear of daily use.

7. Automotive Applications

In the automotive world, LLDPE proves its worth by contributing to components like fuel tanks, interior trim, and bumper parts. Its impressive impact resistance and durability allow it to endure the stresses of the road, while its lightweight nature helps improve fuel efficiency. Whether it’s absorbing shocks or maintaining structural integrity, LLDPE is a trusted ally in vehicle manufacturing.

These are just a few of the most important low density polyethylene properties and uses. This versatile and wonderful material is designed to be used in many projects. Once you use this product, you will realize its key features and benefits.

Agricultural films are products that are not easily manufactured. By using lldpe, you can transform the manufacturing and design process of this product. Apart from this, these products can be used in the design of various geomembranes and industrial liners. These insulating sheets are designed to significantly prevent energy waste. This has also multiplied the importance of these products. By purchasing the best and highest quality lldpe models, you can achieve the desired results and efficiency.

Also, companies active in the field of designing various types of stretch packaging and new toys are interested in using lldpe. This material has good flexibility and can be formed into various shapes and designs. As a result, you can achieve the desired efficiency by using it.

Differences between LLDPE, LDPE and HDPE

Here is a comparison of linear low density polyethylene properties with other types:

| Property / Aspect | LLDPE | LDPE | HDPE |

|---|---|---|---|

| Molecular structure | Linear backbone with short, controlled branches | Highly branched, less regular structure | Mostly linear chains with very few branches |

| Density | Lower than HDPE, slightly higher than many LDPE grades | Low density | Highest density among common polyethylene grades |

| Flexibility | Very good flexibility, especially in thin films | Very flexible and soft | More rigid and less flexible |

| Tensile and puncture strength | Higher tensile strength and puncture resistance than LDPE in films | Lower tensile and puncture resistance compared to LLDPE in films | High tensile strength, especially in rigid parts |

| Rigidity | Less rigid than HDPE | Least rigid (softest) | Most rigid |

| Typical film thickness use | Strong, thin films where toughness and stretch are needed | General purpose films where softness and clarity are important | Less common for very thin stretch films |

| Main flexible uses | Stretch films, agricultural films, flexible packaging | General packaging films, bags, foils | Limited flexible use compared to LLDPE |

| Main rigid uses | Some molded parts and components where flexibility is required | Limited rigid applications | Pipes, containers, blow molded and injection molded rigid products |

Advantages and Disadvantages of LLDPE

Why Choose Linear Low-Density Polyethylene (Advantages)

- Strong toughness and puncture resistance

- Excellent flexibility and elongation

- Often better ESCR than many alternatives in similar conditions

- Enables down-gauging for many film products

- Widely available in multiple grades for film, molding, pipe, and cable

Limitations of LLDPE Polymer (Disadvantages)

- Can be more demanding to process than LDPE (higher torque/energy in some lines)

- Often hazier/lower gloss than LDPE in many film structures

- Grade selection matters: a mismatch can cause sealing or handling issues

Conclusion

Linear Low-Density Polyethylene (LLDPE) combines toughness, flexibility and chemical resistance, making it a reliable choice for films, pipes, cables and molded products in many industries. By selecting high‑quality LLDPE grades with proven technical documentation, converters and manufacturers can improve product performance, reduce processing issues, and optimize costs in both local and export projects. For updated prices, grade recommendations, and detailed support on packaging, agricultural, pipe, or cable applications, contact our team to discuss the best LLDPE solution for your business.