Global Petrochemical Solutions – Your Reliable Export Partner

Shobeir Shimi is a premier supplier and exporter of high-grade petrochemical raw materials, connecting industries worldwide with the resources they need to innovate and grow. With a robust global logistics network and a deep understanding of international trade, we provide a seamless, end-to-end procurement experience for our B2B partners.

Our commitment extends beyond mere supply. We offer a comprehensive suite of export services designed to simplify your purchasing process, ensuring timely delivery and full compliance with international standards.

Flexible Bulk & Customized Supply

Fulfilling orders of any size, from single containers to large bulk shipments, tailored to your exact needs.End-to-End Global Logistics

We manage everything from secure export packaging to reliable worldwide shipping, ensuring safe and timely delivery.

Hassle-Free Documentation & Compliance

We handle all export permits, customs paperwork, and regulatory compliance so you can avoid delays.Dedicated Full-Service Support

A single point of contact manages your entire order, providing expert support from inquiry to final delivery.

Proven Excellence in Global Markets

We have a proven track record of successfully delivering high-quality petrochemicals to a diverse range of industries across the globe.

Our strategic location and logistics expertise have enabled us to build strong trade relationships with partners in over 14 countries, including:

Iraq, Pakistan, India, Turkey, Afghanistan, Uzbekistan, Russia, Taiwan, Indonesia, Spain, Egypt, Poland, Bangladesh, and Tajikistan

Client Testimonials

— Ms. Priya Sharma, Operations Director, ChemTech Industries, India

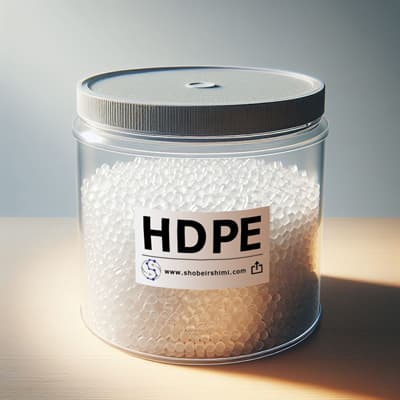

Shobeir Shimi has been an invaluable partner for our HDPE supply in India. Their products consistently meet our quality standards, and their export team ensures smooth delivery and documentation every time.

— Mr. Ahmed Al-Karim, Procurement Manager, Basra Polymers, Iraq

We rely on Shobeir Shimi for our PVC imports to Iraq. Their timely deliveries and professional logistics support make the entire process seamless, from Iran to our facility.

— Mr. Javier Martinez, Supply Chain Director, IberChem Solutions, Spain

Shobeir Shimi provides high-quality polymers with unmatched service. Our operations in Spain have greatly benefited from their reliable supply and expert consultation.

Our Export Product Portfolio

We offer a wide range of polymers and chemicals. Below are our primary export categories with market insights and product specifications.

1. polyethylene (PE)

Polyethylene (PE) is a versatile and widely used thermoplastic valued for its durability, flexibility, and chemical resistance. It is easily molded into countless everyday products, from packaging, pipes, and food containers to automotive parts. Its lightweight and cost-effective nature makes it an exceptionally practical and adaptable material for modern manufacturing.

2. polystyrene (PS)

Polystyrene (PS) is a rigid, transparent, and versatile plastic available in various forms like foam and film. It is widely used for disposable cups, cutlery, and protective packaging due to its lightweight strength and cost-effective production. While caution is advised for hot food applications, its adaptability makes it a popular choice across many industries.

3. Polypropylene (PP)

Polypropylene (PP) is a lightweight thermoplastic valued for its chemical resistance and impact strength. Easily molded and cost-effective, it is widely used in packaging, textiles, and automotive components. Although its recyclability presents environmental challenges, PP remains popular due to its excellent balance of performance and affordability.

4. Polyvinyl Chloride (PVC)

Polyvinyl chloride (PVC) is a highly versatile and widely used plastic material valued for its durability, affordability, and wide range of applications. PVC’s inherent strength and water resistance make it a popular choice in the construction industry for pipes, roofing membranes, and window frames. In the healthcare field, PVC’s flexibility and sterility allow for its use in medical tubing, blood bags, and IV components.

5. polycarbonate (PC)

Renowned for its unmatched toughness and optical clarity, polycarbonate (PC) is a thermoplastic polymer with exceptional strength, durability, and transparency. These qualities make it the material of choice for demanding applications, including bulletproof windows, riot shields, and eyeglasses.

7. Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile Butadiene Styrene (ABS) is a durable thermoplastic prized for its high impact resistance, rigidity, and ease of processing. By combining acrylonitrile’s strength, butadiene’s toughness, and styrene’s rigidity, ABS offers a well-balanced performance for various applications.

8. urea

Urea is a white, crystalline organic compound with the highest nitrogen content (~46%) among solid fertilizers, making it a market leader. Its neutral pH suits various soil types, and it is available in prilled or granular forms. Valued for its cost-effectiveness and high solubility, urea efficiently boosts crop yields and is essential to modern agriculture.

9. ethylene glycol (EG)

Ethylene Glycol (EG) is an essential industrial antifreeze widely used to regulate car engine temperatures in both extreme cold and heat. Its unique properties, including its ability to lower the freezing point and raise the boiling point of liquids, make it indispensable in automotive and industrial cooling systems. However, due to its toxic nature, EG must be handled carefully and stored securely to prevent accidental ingestion by children or pets.

10. COMPOUND

A polymer compound is a substance formed by combining two or more polymers, or a polymer with additional substances, to achieve specific properties that cannot be obtained with a single material. High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), and Linear Low-Density Polyethylene (LLDPE) are the three primary types of polymers that are commonly used in creating polymer compounds.

11. MASTERBATCH

Masterbatch is a concentrated mixture, typically in pellet form, that is blended with virgin plastic resin during the manufacturing process to impart specific properties or aesthetics to the final plastic product. It’s essentially a pre-measured and well-dispersed blend of additives and a carrier resin. There are two main types of masterbatches: The color masterbatch contains pigments or dyes to color the final plastic product. The additive masterbatch contains various functional additives besides colorants that can modify the properties of the plastic.

Your Competitive Advantage with Shobeir Shimi

Guaranteed Quality

All products are sourced from world-class producers and undergo rigorous quality assurance checks before shipment.Best-in-Market Pricing

Our strategic partnerships and efficient supply chain allow us to offer highly competitive pricing without compromising on quality.Logistical Strength

With a network of reliable logistics partners, we ensure secure and on-time delivery to your destination port.Expert Consultation

Our experienced team provides free consultations to help you choose the right product grade and navigate the complexities of international trade.

Request Your Free Quote & Consultation

Ready to secure your supply of high-quality petrochemicals? Our international sales team is here to help.

Contact us today for a no-obligation price quote, to request a product datasheet, or to schedule a free consultation with one of our export specialists.