Polyethylene (PE) and High-Density Polyethylene (HDPE) are ubiquitous plastics, forming the backbone of countless products from consumer goods like children’s toys and food containers to industrial components such as pipes and outdoor furniture. While their inherent durability, chemical resistance, and cost-effectiveness are undeniable advantages, these very attributes present significant hurdles when it comes to aesthetic modification – specifically, painting polyethylene plastic. Many individuals and businesses frequently ask, “Can you paint HDPE?” or “Can you paint polyethylene?” The definitive answer is yes, but achieving a truly durable and attractive finish demands a meticulous approach, specialized knowledge, and the right materials.

This comprehensive guide will thoroughly explore the underlying scientific reasons why these plastics are challenging to paint, demystify the process of polyethylene paint adhesion, and provide detailed, actionable steps and product recommendations. Our aim is to empower you to select the best paint for HDPE plastic and polyethylene, execute the painting process flawlessly, and ensure your polyethylene paint coating stands the test of time.

Understanding the Unique Challenges of Painting Polyethylene and HDPE

The primary reason why painting polyethylene and painting HDPE proves to be a formidable task lies deep within their molecular structure. Both are thermoplastic polymers characterized by exceptionally “low surface energy.” In simpler terms, their surfaces are non-polar, exceptionally smooth, and possess minimal molecular attraction. Imagine attempting to get water to cling to a freshly waxed car; it merely beads up and rolls off. Similarly, conventional paints struggle to “wet out” (spread evenly across) the surface of PE and HDPE, leading to inadequate contact, poor polyethylene paint adhesion, and ultimately, premature peeling, flaking, or scratching.

Beyond low surface energy, several other factors contribute to the difficulty:

- Chemical Inertness: Polyethylene’s high chemical resistance, while beneficial for its primary applications, means it’s impervious to many common solvents found in paints or cleaners that would typically etch or prepare other plastic surfaces.

- Flexibility and Thermal Expansion: Both plastics exhibit a degree of flexibility and significantly expand and contract with temperature fluctuations. A rigid paint film applied to such a dynamic substrate is highly prone to cracking and delamination as the plastic moves.

- Presence of Release Agents: New polyethylene plastic products often come with residual mold release agents from the manufacturing process. These oily residues create an invisible barrier that completely inhibits paint adhesion if not thoroughly removed.

Understanding these inherent hurdles is the foundational first step toward successfully painting HDPE and polyethylene plastic with lasting results.

The Science Behind Achieving Robust Polyethylene Paint Adhesion

To overcome the challenges and achieve strong, lasting polyethylene paint adhesion, we must either chemically alter the surface energy of the plastic or utilize a paint system specifically engineered to bond with low-surface-energy substrates. Traditional paints rely on two primary bonding mechanisms:

- Mechanical Bonding: The paint physically interlocks with microscopic irregularities on the substrate’s surface. Since polyethylene and HDPE are inherently smooth, mechanical bonding alone is insufficient.

- Chemical Bonding: Molecular attraction and chemical reactions occur between the paint and the substrate. This is where the low surface energy of PE and HDPE creates a significant barrier.

The solution lies in specialized primers and surface treatments. Techniques such as flame treatment, plasma treatment, or corona discharge are industrial methods that modify the atomic structure of the plastic’s top layer. They increase its surface energy and introduce reactive polar groups, making the surface far more receptive to forming chemical bonds with a polyethylene paint.

For DIY and smaller-scale applications, adhesion promoters that contain chemicals like chlorinated polyolefins (CPOs) mimic this effect. They act as a bridge, bonding to the non-polar plastic on one side and providing a polar, paint-friendly surface on the other. This creates a receptive foundation, ensuring that your chosen polyethylene paint or HDPE paint can form a durable, chemical bond. Without these crucial preparatory steps, even the best paint for HDPE plastic will inevitably fail to achieve proper HDPE paint adhesion.

Selecting the Best Paint for Polyethylene and HDPE Plastic

Given the unique properties of these materials, not just any “paint plastic paint” will suffice. Success for painting HDPE or polyethylene hinges on selecting specialized products designed specifically for challenging plastics.

Here are the leading product categories for effective polyethylene paint and HDPE paint:

- Specialized Adhesion Promoters (Primers): This is often the most critical component for robust polyethylene paint adhesion. Products like Polyvance’s “Plastic Magic Adhesion Promoter” or similar formulations containing CPOs are engineered to chemically modify the polyethylene surface. They create a molecular bridge, allowing subsequent paint layers to adhere. These are absolutely essential for strong HDPE paint adhesion and are the answer to “can hdpe be painted?” successfully. Some “all-in-one” spray paint for polyethylene products claim to have integrated adhesion promoters, but separate application is often superior.

- Flexible Acrylic Lacquers and Enamels (with Adhesion Promoter): Once an appropriate adhesion promoter is applied and fully cured, high-quality acrylic lacquers or enamels specifically formulated for plastics can serve as an excellent topcoat. Look for paint products that emphasize flexibility and are designed for use on outdoor plastics. Their inherent flexibility allows the paint film to withstand the expansion and contraction of the plastic substrate, preventing premature cracking and peeling. When searching for a “spray paint for polyethylene,” these flexible acrylic options are typically what you’re looking for.

- Two-Part Paints (e.g., Urethanes or Specific Epoxies): For maximum durability, chemical resistance, and superior HDPE paint adhesion, particularly in industrial, automotive, or high-wear applications, two-part urethane or specialized epoxy paint systems are highly effective. Products like some automotive refinishing systems (e.g., Surfacer 2000, as you mentioned) are designed for demanding plastic substrates. These systems require precise mixing of a base and a hardener, creating a much tougher and more resilient polyethylene paint coating. They often perform best when combined with advanced surface preparation like industrial flame treatment.

- Flexible Polyolefin-Specific Coatings: Some advanced manufacturers offer direct-to-plastic paint systems explicitly engineered for polyethylene and HDPE. These often integrate adhesion technology directly into the paint, potentially requiring less intensive pre-treatment compared to standard paints. These innovative solutions provide excellent “PE paint” options.

- Vinyl Dye/Paint: While technically a “dye” rather than a traditional opaque paint, vinyl dyes actually chemically stain the plastic itself. They penetrate the surface and form a molecular bond, offering an incredibly durable and flexible color change without a thick surface coating that could chip. This is an excellent alternative for changing the color of plastic items without dealing with typical paint adhesion issues.

When considering “can you paint HDPE” or “can you paint polyethylene,” remember that the judicious choice of paint is secondary only to the rigor of your surface preparation and the use of appropriate adhesion-promoting products. The “best paint for HDPE plastic” is one that works synergistically with your chosen preparation method.

Essential Preparation Steps for Painting Polyethylene and HDPE Surfaces

Proper surface preparation is not merely important; it is absolutely paramount for successful polyethylene paint adhesion. Skipping or rushing these steps will almost certainly lead to immediate frustration and rapid failure of your paint coating, regardless of the polyethylene paint you choose.

1. Thorough Cleaning and Degreasing:

- Begin by meticulously cleaning the entire polyethylene or HDPE surface.

- Use a strong degreasing cleaner (e.g., trisodium phosphate (TSP) solution, automotive degreaser, or industrial-strength cleaner designed for plastics) or isopropyl alcohol. These are crucial for removing all dirt, grime, oil, grease, and, critically, any invisible mold release agents left over from the manufacturing process. These residues are notorious for preventing paint adhesion.

- Scrub the surface well. Rinse thoroughly with clean water until all soap residue is gone, and allow the plastic to dry completely, ensuring no moisture remains.

2. Light Scuff Sanding (Optional but Highly Recommended):

- While polyethylene is too smooth for significant mechanical bonding, a light scuff with fine-grit sandpaper (around 220 to 320 grit) can still offer benefits. This creates a very slight increase in surface area and helps some primers to “key” into the surface.

- Sand uniformly over the entire area to be painted.

- Crucially, immediately after sanding, wipe away all dust thoroughly with a clean, lint-free cloth, a tack rag, or even compressed air, followed by a final wipe with isopropyl alcohol. Dust will act as a bond breaker.

3. Critical Surface Treatment (Essential for Best Adhesion):

- Flame Treatment (Recommended for HDPE/PE): This is a highly effective, though technical, method for permanently altering the surface energy of polyethylene and HDPE. Using a propane torch, quickly pass the yellow tip of the flame (the less oxidizing part) over the surface. The goal is to briefly cause the surface to “gloss over” without melting or deforming the plastic. This process oxidizes the surface, creating polar groups that readily accept paint. Test the treatment by dropping a few beads of water on the surface: if the water “sheets” or flattens out, the treatment is successful; if it beads up, repeat the flame treatment. This is often the ultimate answer to how to paint HDPE for maximum durability.

- Specialized Adhesion Promoter: If flame treatment is not feasible or desired, apply a commercial adhesion promoter specifically designed for polyolefins (polyethylene, HDPE, polypropylene, etc.). These come in spray cans or liquid form. Follow the product’s instructions precisely for application thickness and drying time. This chemical bridge is vital for establishing initial polyethylene paint adhesion.

4. Primer Application:

- Once the surface treatment (e.g., flame treatment) has cooled or the adhesion promoter is dry according to its instructions, immediately apply a thin, even coat of a primer specifically formulated for plastics or low-surface-energy materials. This layer provides a stable, paint-ready base for your chosen polyethylene paint.

- Allow the primer to dry completely to the touch, following the manufacturer’s recommended drying time. Avoid applying too much primer in one go; multiple thin coats are always superior to a single thick coat for optimal polyethylene paint adhesion and a smooth finish.

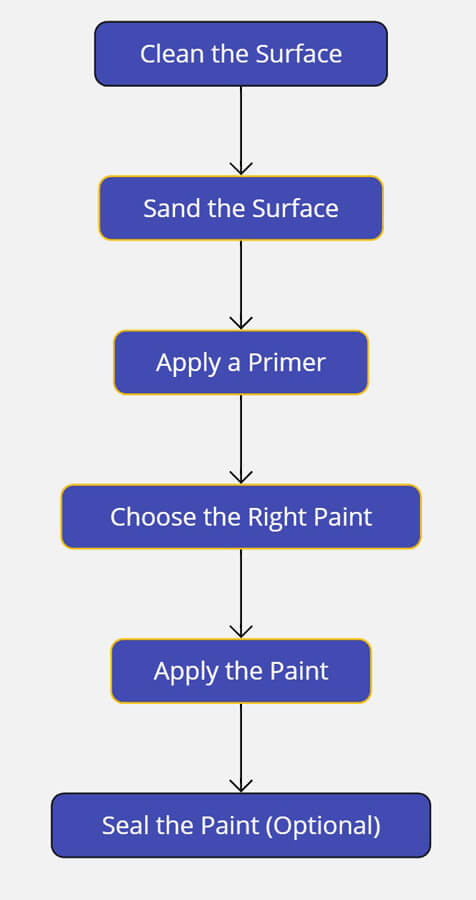

Step-by-Step Guide: How to Paint HDPE and Polyethylene Effectively

With your materials ready and surfaces meticulously prepared, follow these steps for a durable polyethylene paint coating or HDPE paint finish:

- Gather All Materials: Collect your polyethylene or HDPE item, all cleaning supplies, sandpaper (if scuffing), flame torch (if applicable), adhesion promoter/primer, your chosen polyethylene paint (or hdpe paint), protective gear (gloves, safety glasses, respirator), and painter’s tape or masking if needed for crisp lines.

- Execute Surface Preparation: Perform the thorough cleaning, optional scuff sanding, and crucial surface treatment (flame treatment or adhesion promoter application) as detailed in the previous section. Allow all products to dry completely between steps.

- Apply Primer: Once the surface is ready, apply a thin, even coat of your plastic-specific primer. Ensure complete coverage without drips or runs. Allow the primer to dry fully according to the manufacturer’s instructions. This foundational layer is key for polyethylene paint adhesion.

- Apply Topcoat (Polyethylene Paint/HDPE Paint):

- Once the primer is dry, apply thin, even coats of your chosen polyethylene paint or HDPE paint.

- If using spray paint for polyethylene, hold the can at the manufacturer’s recommended distance (typically 10-12 inches) and use smooth, consistent sweeping motions. Overlap each pass slightly to ensure uniform coverage.

- Avoid applying too much paint at once, as this can lead to drips, poor curing, and compromised paint adhesion.

- Allow each coat to dry to the touch (usually 15-30 minutes, check product instructions) before applying the next.

- Cure Time: This is a frequently overlooked but vital step. Allow the paint to fully cure according to the manufacturer’s recommendations. This can range from 24 hours to several days or even weeks for some two-part systems to achieve maximum hardness and HDPE paint adhesion. Do not subject the item to heavy use, scratching, or stress until the paint has completely cured.

Maximizing HDPE Paint Adhesion and Overall Durability

Beyond the fundamental steps, these advanced tips will ensure superior HDPE paint adhesion and a truly long-lasting finish:

- Optimal Environmental Conditions: Always paint in a well-ventilated area with moderate temperature and humidity, ideally between 60-80°F (15-27°C) and 40-60% relative humidity. Extreme conditions (too hot, too cold, too humid) can negatively affect polyethylene paint adhesion, curing times, and the overall finish.

- Embrace Thin Coats: This cannot be overstressed. Multiple thin coats consistently promote better bonding, reduce the likelihood of drips and sags, and create a more flexible, durable paint film that can withstand the plastic’s movements.

- Prioritize Flexibility: When selecting a paint for polyethylene, always choose one that is designed to be flexible. This elasticity allows the paint film to expand and contract in sync with the plastic substrate, significantly preventing unsightly cracking and peeling over time.

- The Power of Test Pieces: Before embarking on your main project, always perform a test application. Use a scrap piece of the identical plastic or an inconspicuous area on the item itself. This allows you to verify compatibility between your plastic, adhesion promoter, and paint, and helps you perfect your application technique, especially when you’re figuring out “can hdpe be painted” with a new product.

Common Pitfalls: Mistakes to Avoid When Painting Polyethylene Plastic

Knowing what to avoid is as crucial as knowing what to do for successful painting polyethylene plastic:

- Neglecting Surface Preparation (The #1 Mistake): This is the most common and fatal error. Without proper cleaning, degreasing, and surface modification (flame treatment or adhesion promoter), your polyethylene paint simply will not stick, leading to immediate failure.

- Using the Wrong Paint: Standard acrylics, latex, or oil-based paints not specifically formulated for plastics or low-surface-energy materials will fail prematurely. They lack the necessary adhesion properties and flexibility. Avoid any generic “paint plastic paint” and always look for products explicitly designed for polyethylene or polyolefins.

- Applying Thick Coats: This common impatience leads to poor drying, unsightly drips, uneven curing, and a brittle paint film highly prone to cracking and peeling, severely compromising polyethylene paint adhesion.

- Rushing Cure Time: Impatience is detrimental to the final bond strength. Allow the paint to fully cure according to the manufacturer’s instructions before handling or putting the item into service. Premature stress can ruin the paint job.

- Ignoring Residual Contaminants: Even after cleaning, microscopic residues like mold release agents can remain. Without an effective degreaser and/or an adhesion promoter, these will act as bond breakers.

Expert Tips for a Flawless Polyethylene Paint Coating

For a truly professional and high-quality polyethylene paint coating, consider these additional insights:

- HVLP Spray Systems: For larger projects or achieving the smoothest possible finish, an HVLP (High Volume Low Pressure) spray paint system can provide an incredibly even and fine paint coating with minimal overspray. This offers superior control compared to aerosol cans.

- Automotive-Grade Finishes: For items requiring extreme durability, UV resistance, and a premium aesthetic (e.g., custom HDPE automotive parts or outdoor gear), research automotive-grade paint systems designed specifically for plastic bumpers and trim. These often offer the best HDPE paint adhesion and chip resistance available.

- Clear Coats/Sealants for Added Protection: Applying a clear, flexible topcoat sealant formulated for plastics after the final paint has cured can add an invaluable extra layer of protection. This enhances resistance against UV degradation, abrasion, impact, and environmental elements, significantly extending the life and vibrancy of your polyethylene paint job.

- Professional Consultation: For very specific, critical, or complex projects, or if you’re working with unusual types of polyethylene, do not hesitate to consult with a local professional paint supplier, an industrial coatings specialist, or even the technical support of paint manufacturers. They can provide tailored recommendations for the best paint for HDPE plastic or other polyethylene variants specific to your application.

Conclusion: Mastering the Art of Painting HDPE and Polyethylene

While the low surface energy and inherent flexibility of polyethylene and HDPE present considerable challenges, the knowledge of how to paint HDPE and polyethylene effectively is now firmly within your reach. The cornerstone of success lies in a meticulous understanding of the material’s properties and the strategic application of specialized primers, adhesion promoters, and flexible paints designed to overcome these hurdles.

By diligently cleaning and preparing the surface, applying appropriate adhesion promoters, selecting the best paint for HDPE plastic (or general polyethylene), and applying thin, even coats with patience, you can achieve remarkable polyethylene paint adhesion and a durable, attractive polyethylene paint coating that truly transforms these versatile plastics. So, for your next project involving a polyethylene plastic item, or if you’re still asking “can hdpe be painted?”, you now possess the comprehensive knowledge and confidence to proceed like a professional, armed with the right PE paint and techniques for lasting results.

درج دیدگاه