Polyethylene is one of the most commonly used synthetic polymers worldwide. It is a thermoplastic made from the polymerization of ethylene monomers, often used in applications ranging from plastic bags to pipes. Polyethylene is known for its versatility, low cost, and ease of processing, making it a key material in packaging, consumer goods, and even the medical sector.

Polyvinyl chloride (PVC) is a synthetic plastic polymer derived from vinyl chloride monomers. It is primarily used in construction, electrical, and healthcare industries and stands out due to its rigidity and resistance to environmental degradation.

The two differ significantly in terms of chemical properties, flexibility, and usage when comparing polyethylene vs. polyvinyl chloride. Polyethylene tends to be more flexible and resistant to moisture, while PVC is more rigid and has excellent resistance to chemicals and environmental elements. Both materials have established niches but excel in different areas—polyethylene in packaging and PVC in piping systems and construction materials like flooring.

Chemical Composition of Polyethylene and Polyvinyl Chloride

Polyethylene’s molecular structure consists of long chains of ethylene units (C2H4), which are simply repeated throughout the polymer. The result is a material that can be tailored for different properties, such as low-density polyethylene (LDPE) for flexible, soft products, or high-density polyethylene (HDPE) for harder, stronger items. This ability to modify the polymer’s structure allows for a wide range of applications.

polyvinyl chloride has a more complex structure, where the vinyl chloride monomer (C2H3Cl) polymerizes to form a chain with chlorine atoms attached to the backbone. This chlorine atom imparts properties such as improved resistance to fire and chemical corrosion. PVC comes in two main forms: rigid PVC (uPVC), used primarily for construction and piping, and flexible PVC, which incorporates plasticizers for applications like flooring or electrical insulation. The key difference between the two polymers lies in their backbone structure, which directly influences their mechanical properties and how they are used in various applications.

Production Process of Polyethylene and Polyvinyl Chloride

Polyethylene production typically involves the polymerization of ethylene, usually via a high-pressure process or catalytic methods like Ziegler-Natta catalysis. High-pressure methods create low-density polyethylene (LDPE), while more controlled methods, like low-pressure polymerization, produce high-density polyethylene (HDPE). Each production method impacts the material’s density, strength, and flexibility, making the production process a critical factor in determining the polymer’s final properties.

Polyvinyl chloride is produced by polymerizing vinyl chloride in suspension, emulsion, or bulk processes. The production of PVC is more energy-intensive than polyethylene, largely due to the need for chlorine gas, which is generated from salt. While PVC is versatile in its applications, its production has raised environmental concerns, particularly related to chlorine-based byproducts. When comparing their production processes, the environmental impact is more pronounced in PVC, especially considering the chlorine used in its manufacturing process and the potential for harmful emissions.

Physical Properties of Polyethylene and Polyvinyl Chloride

The density of polyethylene varies depending on its type—HDPE has a density around 0.941-0.965 g/cm³, while LDPE has a lower density of 0.910-0.940 g/cm³. These differences in density contribute to the strength and rigidity of the material, with HDPE being more robust and suitable for heavy-duty applications such as containers and pipes. Polyvinyl chloride, in contrast, has a density range of 1.3-1.45 g/cm³, making it denser and more rigid than most types of polyethylene. This rigidity makes PVC a preferred choice for applications that require structural integrity, like plumbing and window profiles.

In terms of flexibility and durability, polyethylene or PVC chloride shows stark contrasts. Polyethylene, particularly LDPE, is highly flexible and resistant to low temperatures, making it ideal for packaging films and flexible tubing. PVC, though, is generally more rigid but can be made flexible with additives, allowing it to be used in applications like inflatable products or flexible electrical cables. PVC’s higher rigidity and resistance to UV degradation give it a distinct advantage in outdoor and construction settings.

| Property | Polyethylene(HDPE) | Polyethylene (LDPE) | Polyvinyl Chloride (PVC) |

|---|---|---|---|

| Density (g/cm³) | 0.941-0.965 | 0.910-0.940 | 1.3-1.45 |

| Column 1 Value 2 | High | Low | High |

| Flexibility | Low | High | Low-Medium (with additives) |

| Temperature Resistance | Good | Excellent | Good |

| UV Resistance | Poor | Poor | Good |

| Typical Applications | Containers, pipes | Packaging films, tubing | Plumbing, window profiles, construction, electrical cables |

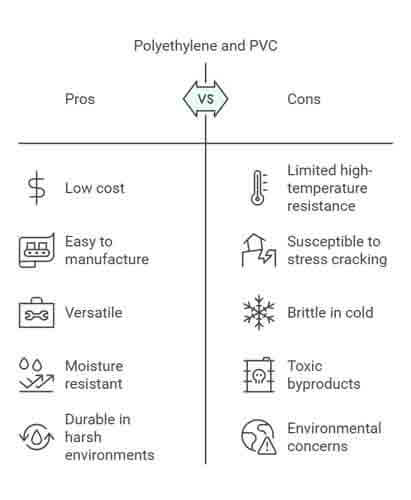

Advantages and Disadvantages of Polyethylene and Polyvinyl Chloride

The advantages of polyethylene are abundant, starting with its low cost, ease of manufacture, and versatility. Its resistance to moisture, chemicals,s and impact makes it an excellent choice for food packaging, trash ba, gs, and even medical applications like catheters. However, polyethylene’s disadvantages iincludeits limited ability to withstand high temperatures and its susceptibility to stress cracking, especially in HDPE forms.

Polyvinyl chloride has its own set of strengths, such as high rigidity, strength, and fire resistance. It is particularly durable in harsh outdoor environments and resists corrosion from chemicals and moisture, which is why it is often used in pipes and construction materials. On the downside, PVC can be brittle in cold temperatures and releases toxic chlorine-based byproducts during production and disposal, raising concerns about its environmental impact. Therefore, the polyethylene vs polyvinyl chloride comparison emphasizes PVC’s superior structural properties for construction, while polyethylene remains the champion in flexibility and ease of use.

Applications of Polyethylene and Polyvinyl Chloride in Different Industries

In the packaging industry, polyethylene is widely used in the production of plastic films, bags and bottles due to its flexibility, strength and cost-effectiveness. For example, polyethylene’s ability to form thin, durable films makes it perfect for food packaging, such as bread bags and milk containers. Polyvinyl chloride, conversely, is extensively used in the construction industry, particularly for plumbing and electrical applications. PVC pipes are a staple due to their excellent chemical resistance and strength.

Both polymers have diverse applications in healthcare. Polyethylene is commonly found in medical devices such as syringes, tubing, and prosthetics due to its biocompatibility and ease of sterilization. PVC is also used in healthcare, primarily for products like blood bags, medical tubing,g and flooring, offering high chemical resistance and durability. Thus, polyethylene vs polyvinyl chloride reveals that while both materials are widespread across industries, they serve different, specialized roles in each field.

Environmental Impact and Sustainability of Polyethylene and Polyvinyl Chloride

-

Recyclability:

Polyethylene is widely recycled, particularly HDPE, which can be repurposed into new products like containers and plastic lumber. Its recyclability is a strong advantage, but limited collection rates and improper disposal reduce its effectiveness in addressing waste concerns.

PVC is less commonly recycled due to its complex composition and the presence of additives like chlorine. However, advancements in recycling technologies are improving its potential for reuse, particularly in construction applications where durability can offset its environmental cost.

-

Pollution Concerns:

Polyethylene, due to its lightweight and non-biodegradable nature, is a major contributor to plastic pollution, often found in oceans and ecosystems. Efforts to curb its impact include better waste management and eco-friendly alternatives.

PVC poses greater toxicity risks during production and disposal. Chlorine-based emissions and harmful additives remain significant concerns, though its longevity in applications like pipes and construction materials can mitigate its environmental footprint over time.

Cost Comparison of Polyethylene and Polyvinyl Chloride

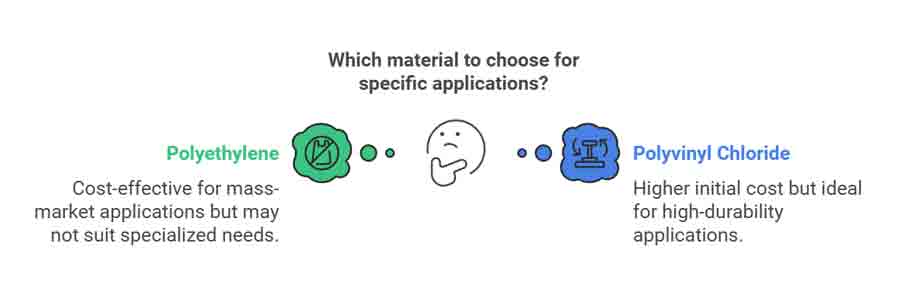

The cost of polyethylene is relatively low due to its simple production process and abundant raw materials. This makes it an ideal choice for mass-market applications like plastic bags, food packaging and consumer goods. However, the cost can rise for specialized polyethylene products such as those used in the medical or automotive industries, which require higher-performance grades.

Polyvinyl chloride tends to be more expensive to produce due to its complex manufacturing process, particularly the chlorine extraction and polymerization steps. Despite this, PVC is often more economical for specific high-durability applications like plumbing or flooring, where its long lifespan and low maintenance outweigh the initial cost. Comparing polyethylene vs polyvinyl chloride, polyethylene often offers cost savings in terms of raw materials and production, while PVC justifies its higher cost through its longevity and specialized applications.

Conclusion and Final Thoughts

Polyethylene and polyvinyl chloride (PVC) are two versatile polymers that have revolutionized industries worldwide. Their unique properties cater to distinct needs:

- Polyethylene is celebrated for its flexibility, moisture resistance, and cost-effectiveness, making it ideal for packaging, medical applications, and lightweight consumer goods.

- PVC, on the other hand, excels in durability, rigidity, and chemical resistance, making it a go-to choice for construction, piping, and electrical applications.

When choosing between polyethylene and PVC, the decision ultimately depends on the specific application requirements—whether it’s flexibility and low cost or structural strength and longevity. However, both materials face challenges regarding environmental impact, emphasizing the need for improved recycling technologies and sustainable alternatives to reduce their ecological footprint.

Understanding the strengths and limitations of these polymers allows industries to make informed decisions, balancing functionality, cost, and sustainability for a better future.

Leave A Comment