The industrial sector uses HDPE as a widely accepted polymer for applications in packaging, construction, automotive, and healthcare industries. The polymer family recognizes HDPE as one of its most durable products because of its versatility and cost-effective nature. The utilization of high-density polyethylene requires evaluation of its advantages and disadvantages, which exist alongside every other material. Understanding the pros and cons of HDPE helps businesses determine the appropriate uses of this material for distinct projects. Here, we provide an extensive examination where we evaluate the advantages together with the limitations of HDPE while discussing its industrial significance.

What is High-Density Polyethylene (HDPE)?

The HDPE material requires a fundamental definition before discussing its advantages and disadvantages. Due to its base in petroleum, HDPE represents one type of thermoplastic polymer. Its highest strength-to-density composition allows the material to combine weightlessness with robustness. The carefully arranged polymers in their molecular structure produce both high strength and enhanced rigidity and durability. Industry uses HDPE to produce bottles as well as pipes and plastic products but also utilizes the material in applications such as engineering components and landfill liners, which require wear resistance.

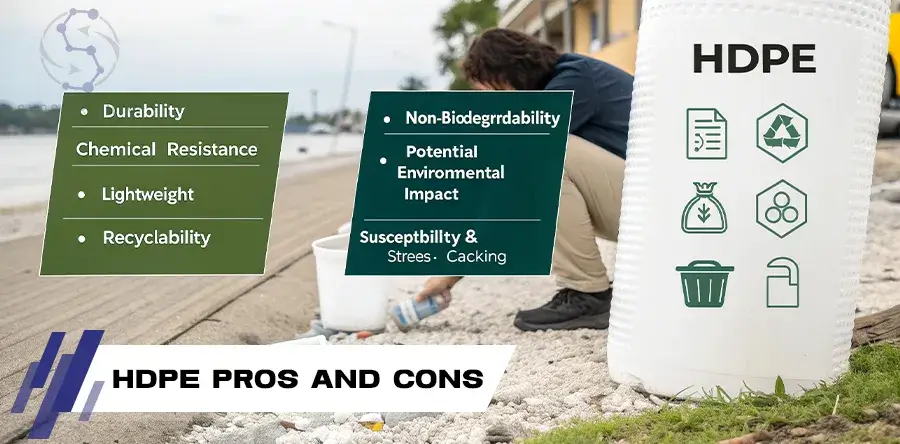

High-Density Polyethylene Benefits

People across the globe consider HDPE to be one of the most beneficial materials available today. High-density polyethylene finds use in many applications because it demonstrates strength while offering resistance to chemicals and remains environmentally friendly. The subsequent section provides detailed information about the main benefits that HDPE offers as a material.

Durability and Longevity

The distribution sector heavily relies on high-density polyethylene because it provides remarkable durability as a primary advantage. HDPE remains unaffected by various aggressive substances such as acids, alcohols, and oils. The material resists temperatures that range between cold and extremely hot environmental conditions. The outstanding resistance of HDPE toward various environmental elements makes it appropriate for outdoor utility and industrial deployments. HDPE pipes dominate water distribution applications because solar ultraviolet rays and chemical interactions cannot affect them the same way other materials weaken.

Environmental Resistance

The resistance of HDPE to environmental elements represents its major advantage. This natural resistance to damage by corrosion allows HDPE to function as an excellent material choice for water-exposed areas like seashore zones and wetlands. Time exposure to salts, oils, acids, and other chemical substances does not degrade HDPE because of its chemical resistance properties. Additionally, it demonstrates lengthy operational capabilities, which decreases the need for both replacements and required maintenance.

Lightweight and Cost-effective

The strength of HDPE does not equate to excessive weight, as this material remains lightweight, thus facilitating transportation and handling operations. The substance provides special advantages for big projects that need to transport and construct expensive, heavy materials. The low price of HDPE makes it a preferred material for manufacturers to reduce their costs in production. Due to its combination of low cost and long service life, industrial operations across agriculture and consumer manufacturing find HDPE an attractive material choice.

Recyclability

HDPE offers a prominent benefit through its capability to be recycled several times. As one of the recyclable plastics, HDPE holds the number 2 designation in recycling standards, allowing the manufacturing of fresh products from recycled materials. The sustainability advantage of HDPE has boosted its industrial popularity since manufacturing companies aim to fulfill sustainability objectives. Plastic bottles, together with other consumer products, use recycled HDPE material to produce new products while minimizing the consumption of fresh materials and advancing circular economy activities.

Versatility

HDPE presents such versatility that it lets it function across various applications, from the food business to construction needs. HDPE serves as the fundamental material for producing packaging containers, toys, and medical devices. The material can be shaped for manufacturing purposes and applied in multiple industries through flexible procedures, making it the top choice for production segments across the market. Production processes benefit from the flexible material properties of HDPE because the substance is shaped into various sizes and forms according to each production requirement.

High-Density Polyethylene Drawbacks

The extensive list of advantages of HDPE does not eliminate the disadvantages that the material presents. The performance of HDPE materials might encounter certain restrictions depending on their designated use. The following section investigates both the benefits and drawbacks of HDPE material.

1. Vulnerability to UV Radiation

HDPE maintains durability in most environmental conditions, yet it becomes sensitive to ultraviolet (UV) radiation, which induces gradual deterioration. The damage caused by ultraviolet light represents a major issue for HDPE plastic products placed outside where they receive direct sun exposure. Exposure to UV rays deteriorates HDPE by making it brittle while weakening its material strength. The negative effect of UV radiation exposure on HDPE products can be reduced through the implementation of UV stabilizers in combination with protective coatings.

2. Limited High-Temperature Resistance

The melting point of HDPE stays below the thresholds of polycarbonate or PTFE (polytetrafluoroethylene), despite its ability to function in temperatures between cold and moderate heat. Individual HDPE items start to deform when heated to 120°C (248°F), yet they may experience material failure above that temperature threshold. Applications that need temperature resistance exceeding 120°C (248°F) make HDPE an unsuitable material.

3. Stiffness at Low Temperatures

The brittleness of HDPE increases during cold temperatures, making this material ill-suited for environments with freezing temperatures or below-freezing conditions. The widespread use of HDPE pipes stops short in temperature regions with intense cold. Industrial production of materials for cold-temperature applications requires manufacturers to select alternative manufacturing materials.

4. Poor Aesthetic Qualities

The dull appearance of HDPE makes many people disqualify it for their applications. The transparent and shiny appearance, which stems from acrylic or polycarbonate materials, is absent from HDPE products. Products that require visually attractive appearances will find better performance with an alternative material instead of HDPE. Function takes precedence over appearance considerations when using this material for industrial applications.

5. Challenges with Welding and Bonding

Specialized welding methods along with instruments become necessary to bond HDPE since the material features low surface energy levels. Bonding HDPE components becomes more technologically demanding as opposed to other materials, which facilitates easy bonding processes. HDPE welding needs precise heat and pressure applications because improper techniques result in either weak joints or total product failure during usage.

How SHOBEIR SHIMI Supports HDPE Applications

SHOBEIR SHIMI demonstrates excellence by delivering premium polymer materials as well as chemicals, compounds, and masterbatches, all of which comply with industry standards. The petrochemical product import and petrochemical product export business positions SHOBEIR SHIMI to fully understand the importance of dependable HDPE materials for our clients. SHOBEIR SHIMI delivers HDPE materials that exceed quality control requirements, guaranteeing consistent performance in all manufacturing, construction, and packaging industries.

Due to our expertise in the world polymer market and our extensive supplier connections, SHOBEIR SHIMI has become a top choice for Iran HDPE exporters. Our company brings products to market that enhance production systems and adapt perfectly to customer-specific requirements.

Conclusion

The versatile, durable material called high-density polyethylene features resistance to chemicals, extended environmental survival ability, and recycling possibilities. Its reliable performance, along with cost-effective characteristics, makes HDPE an excellent material selection for industry uses. The material experiences two main drawbacks, which include UV radiation sensitivity and restricted usage at high temperatures.

The examination of both the strengths and weaknesses of HDPE enables industries to determine if this material suits their particular requirements. The high-quality HDPE products from SHOBEIR SHIMI allow organizations to achieve their manufacturing objectives by using a sustainable solution that delivers both budget benefits and ecological advantages.

Leave A Comment