In packaging, HDPE vs PET are two of the most common thermoplastics. Both are very important in some applications, including HDPE vs PET for food packaging, medicine, and household products. With that noted, HDPE and PET also have some similarities that might be very influential in the choice of material for particular applications.

The purpose of PET and HDPE meaning comparison is to contrast the unique attributes, strengths, and weaknesses of each plastic and assist you in making an effective choice based on cost, greenness, recycles, and requirements for particular applications.

What is PET (Polyethylene Terephthalate)?

PET (Polyethylene Terephthalate) is a thermoplastic polyester resin. Because of its versatility and high clarity, PET is a commonly used thermoplastic polyester resin for many packaging applications.

Key Properties of PET:

- Transparency/Clarity: PET is glass-like in appearance and thus well-suited for products that need to be highly visible.

- Strength & Rigidity: Though less stiff than HDPE, PET possesses better strength, which is robust without being too heavy.

- Lightweight: PET is significantly lighter than most other plastics, reducing shipping costs and environmental impact.

- Excellent Barrier Properties: It is extremely good at preventing moisture, gases, UV light, oils, and chemicals from entering or leaving, maintaining its contents in a fresh condition.

- Chemical Resistance: PET is resistant to a variety of corrosive chemicals, such as diluted acids, oils, and alcohols.

- Thermal Stability/Temperature Range: PET has properties under a moderate temperature range but is not as heat-resistant as HDPE.

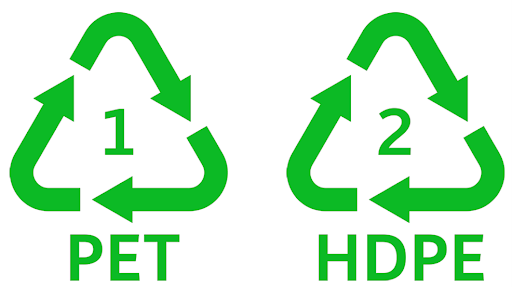

- Recyclability: PET is highly recyclable and has the recycling code “1,” thus it is an environmentally friendly option for packaging.

Common Uses of PET:

- General Applications: PET is widely applied in beverage packaging, food packaging, and films.

- Pharmaceutical Uses: PET is also critical in the pharmaceutical industry for products such as medicine bottles, pill packs, vials, and diagnostic kit boxes.

Limitations of PET:

- Less Resistance to High Temperatures: PET possesses a lower resistance to high temperatures compared to HDPE.

- Weak Acid Resistance: PET is not resistant to strong acids, which can be a drawback in some industrial uses.

What is HDPE (High-Density Polyethylene)?

HDPE (High-Density Polyethylene) is one of the widely utilized thermoplastics that is derived from petroleum, and obtained by polymerization. As a very dense, linearly configured polyethylene, HDPE vs PET contrasts the difference in their chemical composition and nature in the way they find use in packaging and elsewhere.

Key Properties of HDPE:

- High Density: HDPE’s specific density range provides enhanced strength and stability.

- Strength, Stiffness, and Rigidity: HDPE is highly resistant to compression, making it ideal for heavy-duty applications.

- High Impact Resistance: HDPE is good in compression resistance and is well suited for heavy-duty usage.

- Flexibility: Despite its rigidity, HDPE is relatively flexible compared to other rigid plastics.

- Chemical Resistance: HDPE is strongly resistant to acids, bases, alcohols, and the majority of chemicals, with a long life in harsh environments.

- Moisture Resistance: It is impermeable and gives an excellent water vapor barrier, which is suitable for packaging that is sensitive to moisture.

- UV Resistance: HDPE has resistance to degradation from UV light, with extended outdoor performance.

- Thermal/Temperature Resistance: It is good in freezing and hot temperatures, with better heat resistance than PET.

- Recyclability: HDPE is very recyclable, classified with the code “2,” encouraging sustainability.

- Appearance: HDPE usually presents an opaque to translucent, natural milky appearance and is thus readily capable of being inspected for fill levels within containers.

Common Uses of HDPE:

- General Applications: HDPE is widely used in manufacturing bottles, containers, and HDPE pipes for various industries.

- Pharmaceutical Uses: It is used in packaging, medicine bottles, pill bottles, and lab equipment.

- Chemical Storage: HDPE can be used to store chemicals that are corrosive due to high chemical resistance.

Limitations of HDPE:

- Incompatible with Strong Oxidizers: HDPE is incompatible with strong oxidizers such as chlorine or concentrated nitric acid.

- Not Easy to Shape into Customized Forms: Relative to PET, HDPE is more difficult to shape into complex or customized forms, restricting its design flexibility.

HDPE vs PET: Key Differences Compared

When comparing PET and HDPE, there are several factors to consider like appearance, strength, flexibility, chemical resistance, temperature range, barrier property, recyclability, and cost. Following is a detailed comparison based on the prominent characteristics of these two plastics.

1. Appearance

The first distinction that can be easily identified between HDPE and PET is appearance. PET will typically be transparent or clear, which makes it ideal for use in products such as water and beverage bottles where transparency of quality is required. HDPE will have an opaque, translucent, or milky look, but both can be color-matched for different design specifications.

2. Strength & Durability

Both HDPE and PET are tough, but their impact resistance and rigidity are different. HDPE will have a higher impact strength, hence higher resilience and less susceptibility to damage, especially in extreme conditions. HDPE is more rigid compared to PET, which is tougher but less impact-resistant. HDPE vs PET durability thus favors HDPE where toughness and rigidity are more required, e.g., in industrial containers.

3. Flexibility of HDPE vs PET

In terms of flexibility, HDPE is very slightly flexible but less so than PET, which is more pliable and flexible. Because it is flexible, PET is a good material to use for making light, flexible packaging such as bottles and film, whereas HDPE is generally used for those products that need a stiffer shape, including containers and pipes.

4. Chemical Resistance

Both PET and HDPE offer excellent chemical resistance, but each excels in a different class. HDPE is resistant to such a wide cross-section of chemicals, including acids, bases, and alcohol, and is very corrosion-resistant. PET also resists very well but performs better when faced with diluted acids, oils, and alcohol. HDPE does not, however, recommend exposure to strong oxidizers or concentrated acids, while PET is restricted when exposed to high temperatures or concentrated acids.

5. HDPE vs PET: Temperature Resistance

Temperature resistance is another one of the main differences between HDPE and PET. HDPE can endure exposure to an enormously wider range of temperatures, from -110°F to 165°F (-78.9°C to 75°C), which makes HDPE perfect for extremely cold applications as well as relatively high-temperature applications. PET, however, is only effective between -40°F and 130°F (-40°C and 55°C), which means it isn’t quite so useful for high-temperature use. Their melting points also vary significantly: HDPE melts between 120°C to 180°C, whereas PET melts at a significantly higher temperature of 240°C to 260°C.

6. Barrier Properties: HDPE vs PET

Both HDPE and PET are fine barrier materials, but PET is rated as superior in this regard. PET is also commonly stated to have a great gas and moisture barrier and is most commonly utilized for packaging soft drinks and juices, among other things. HDPE, though not as effective as PET, is an impermeable barrier material and is particularly noted to have fine water vapor barrier properties. Hence, in packaging considerations of food with HDPE versus PET, PET is normally preferred due to its better oxygen and moisture barrier.

7. Recyclability of HDPE vs PET

They are both highly recyclable, but they fall under different HDPE vs PET recycling codes. PET has the recycling code “1”, while HDPE has the recycling code “2”. Both can be recycled into a range of products, but one should take into account the fact that recycling these two types of plastic in a combined manner might be challenging due to the difference in the properties of the two plastics. HDPE vs. PET recycling effectiveness can vary depending on local recycling facilities and the separation quality of these plastics. They are recycled to the environment’s benefit through lowered waste and conservation of raw material, although PET is more so for consumer product recycling.

8. HDPE vs PET: Cost

In a head-to-head analysis of the cost of HDPE vs PET, HDPE is generally more affordable than PET. HDPE has wide applications across various products due to the generally lower costs of production. PET, with a somewhat higher average cost, is suited to packages with more requirements in clarity, longevity, and barriers, such as those of drinking containers. Thus, the HDPE vs PET cost comparison generally depends on the specific use application and performance characteristics of the material.

Table of difference between hdpe and pet plastic:

| Property | HDPE (High-Density Polyethylene) | PET (Polyethylene Terephthalate) |

|---|---|---|

| Chemical Structure | Polymer of ethylene monomers (C2H4) | Polymer of terephthalic acid and ethylene glycol |

| Density | 0.93-0.97 g/cm³ | 1.38 g/cm³ |

| Strength | High tensile strength, stiff and rigid | High strength, but lower rigidity than HDPE |

| Durability | Excellent impact, weather, and chemical resistance | Good resistance to impact but lower resistance to UV degradation |

| Applications | Bottles, pipes, plastic bags, toys, and containers | Soft drink and water bottles, food packaging, textiles |

| Recyclability | Highly recyclable (Code #2) | frequently recycled into new bottles or fabrics |

| Transparency | Not transparent, easily dyed | Transparent, typically used for transparent containers |

| Cost | Typically less expensive to manufacture than PET | More expensive than HDPE due to production processes |

| Flexibility | Less flexible, harder | More flexible than HDPE, normally used in thin and flexible applications |

| Barrier Properties | Excellent moisture barrier, but poor gas barrier | Outstanding gas barrier to CO2 and oxygen, ideal for preserving freshness |

| Temperature Resistance | Suitable for temperatures up to 120°C (248°F) | Can withstand higher temperatures than HDPE, up to 250°C (482°F) |

| Environmental Impact | More environmentally friendly, lower carbon footprint | Recycling is energy-intensive but highly recyclable |

Which Plastic is Better? Choosing Between PET and HDPE

Deciding between HDPE and PET relies on application. PET (Polyethylene Terephthalate) is best where transparency is a must, i.e., in bottled drinks or liquid medications, and suitable for milder chemicals. Conversely, HDPE (High-Density Polyethylene) performs best when being highly resistant to impacts, and for keeping corrosive chemicals or secondary packing. Knowing how HDPE differs from PET plastic will guide the decision as to which material works for you.

Conclusion

Essentially, what sets HDPE and PET apart is the application’s particular demands. For PET vs HDPE sustainability, PET tends to be more recyclable, while HDPE is celebrated for its physically robust nature. Ultimately, if you’re choosing HDPE vs PET bottles or other items, the best material boils down to factors like durability, chemical resistance, and product clarity.

Leave A Comment