An HDPE pipe, also known as a High-Density Polyethylene Pipe, is a type of thermoplastic piping manufactured from high-density polyethylene resin. When professionals ask what is HDPE pipe or what is HDPE pipes, they are referring to a lightweight, flexible, and completely non-corrosive piping solution widely used for transporting water, sewage, gas, and various industrial fluids.

Thanks to their dense molecular structure, high density polyethylene pipes offer superior mechanical strength and chemical resistance compared to many traditional piping materials. This is why non-corrosive PE pipelines and HDPE piping systems have increasingly replaced metal and concrete pipes in modern infrastructure, urban utilities, and industrial projects.

HDPE Pipe Benefits

The advantages of HDPE pipes go far beyond basic durability. One of the most important HDPE pipe benefits is their complete resistance to corrosion. Unlike steel or iron pipes, HDPE does not rust, scale, or chemically degrade when exposed to water, sewage, salts, acids, or aggressive chemicals. This makes HDPE especially suitable for underground and hard-to-access installations.

Another major advantage of high density polyethylene piping is flexibility. HDPE pipes can absorb ground movement, vibrations, and even seismic activity without cracking or breaking. This flexibility significantly reduces repair costs and system failures over time. In addition, the smooth internal surface minimizes friction losses, prevents sediment buildup, and maintains stable flow capacity for decades—making non-corrosive PE pipelines both a technical and economic long-term solution.

Types of HDPE Pipe

When discussing types of HDPE pipe, it is important to understand that each type is engineered for a specific application. For example, HDPE water pipe is produced using certified, hygienic materials that ensure no impact on drinking water quality. These pipes are widely used in municipal and rural water supply networks.

HDPE pipes for sewage and drainage are designed with a strong focus on chemical resistance and long-term durability in aggressive environments. Meanwhile, HDPE gas pipes must meet stricter safety and pressure standards due to the critical nature of gas transmission. This application-specific design approach ensures that every HDPE pipe delivers optimal safety, performance, and service life.

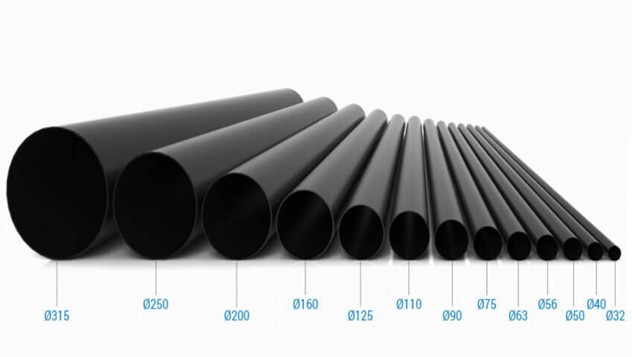

HDPE Pipe Sizes, Dimensions & Diameters

Choosing the correct HDPE pipe sizes is one of the most critical decisions in system design. HDPE pipes are classified based on outside diameter (OD), wall thickness, and SDR ratio, which together determine pressure capacity and performance.

Small-diameter pipes are commonly used in irrigation and residential networks, while larger HDPE pipe diameters are applied in main transmission lines and industrial projects. Understanding HDPE pipe dimensions allows engineers to accurately calculate flow rates, pressure losses, and installation requirements.

HDPE Pipe Size Table

| Diameter Range (mm) | Inch Equivalent | Typical Application |

|---|---|---|

| 20 – 32 | ½ – 1 | Irrigation & residential |

| 40 – 63 | 1.5 – 2 | Water distribution |

| 75 – 110 | 3 – 4 | Urban water & sewage |

| 125 – 225 | 5 – 9 | Transmission lines |

| 250 – 500 | 10 – 20 | Industrial projects |

| 560 – 1600 | 22 – 63 | Large infrastructure |

SDR & Pressure Rating

| Application | Nominal Pressure (PN) | SDR |

|---|---|---|

| High pressure | PN 20 | SDR 9 |

| Drinking & industrial water | PN 16 | SDR 11 |

| Irrigation | PN 12.5 | SDR 13.6 |

| Sewage | PN 10 | SDR 17 |

| Drainage | PN 8 | SDR 21 |

This information directly addresses common searches related to sizes of HDPE pipe and pressure classifications.

HDPE Pipe Fittings

HDPE pipe fittings are essential components that determine the integrity and performance of the entire piping system. Even the highest-quality HDPE pipe can fail if improper fittings are used. Professional HDPE pipes and fittings systems are always selected based on pressure rating, pipe size, and application.

HDPE Elbow

HDPE elbows are used to change flow direction, typically at 45° or 90°. Properly designed elbows minimize turbulence and pressure loss, making them ideal for water and sewage networks.

HDPE Tee

HDPE tees allow branching from a main pipeline. They are commonly used in distribution networks and irrigation systems, where balanced flow and secure joints are essential.

HDPE Reducer

Reducers connect pipes of different diameters and ensure smooth transition of flow. Standard reducers prevent sudden pressure changes that could damage the system.

HDPE Coupling

Couplings are used to connect pipes of the same diameter, often in repairs or line extensions. Electrofusion couplings are especially popular in confined spaces.

Flange Adapter

HDPE flange adapters allow connection to valves, pumps, and metal equipment. They are ideal for systems requiring periodic maintenance.

End Cap

End caps seal pipe ends during pressure testing or future network expansion.

Connection Methods

HDPE fittings are installed using butt fusion, electrofusion, or mechanical fittings, depending on project requirements.

Applications of HDPE Pipes

The versatility of HDPE pipes makes them suitable for a wide range of applications. HDPE water pipes are widely used in potable water systems due to their hygienic properties. In sewage and drainage networks, their chemical resistance and smooth internal surface ensure reliable long-term performance.

In chemical and petrochemical industries, high density polyethylene piping is used to transport corrosive fluids safely. In agriculture, HDPE plays a vital role in modern irrigation systems thanks to easy installation and long service life.

HDPE Water Pipes | Pipes for Water Transmission

HDPE water pipes are specifically designed for potable water, raw water, and industrial water applications. They are manufactured to meet sanitary standards, ensuring no impact on water taste, odor, or quality. With high internal pressure resistance, excellent flexibility against ground settlement, and stable performance across diverse climates, HDPE pipes have become a standard choice in municipal, rural, and industrial water supply networks.

Benefits of HDPE Pipes in Water Transmission

One of the main advantages of HDPE water pipes is their non-corrosive nature, classifying them as non-corrosive PE pipelines. Their smooth interior surface prevents sediment build-up, reduces pressure drop over long distances, and improves overall flow efficiency. Additionally, their flexibility allows water networks to withstand vibrations, temperature fluctuations, and ground movement, minimizing long-term maintenance costs.

HDPE Pipes for Sewage & Drainage | Wastewater and Drainage Applications

HDPE pipes for sewage and drainage are designed for urban and industrial wastewater systems as well as drainage networks. Thanks to their chemical resistance, these pipes are reliable in corrosive environments. They do not degrade when in constant contact with sewage gases, organic matter, or high humidity. Their flexibility also ensures stable performance despite ground settlement or soil shifts, which is crucial for buried wastewater networks.

Key Features in Sewage and Drainage Systems

HDPE pipes have a smooth inner surface that prevents sediment accumulation and blockages, maintaining consistent wastewater flow. Their non-corrosive nature ensures longer service life compared to concrete or metal pipes. Easy installation, secure joints, and minimal maintenance make high-density polyethylene pipes a preferred choice for sewage and drainage projects.

HDPE Pipe Manufacturers | Iranian Manufacturers in the Market

In recent years, the Iranian market has become one of the regional hubs for the production of HDPE pipes. Direct access to petrochemical raw materials, a skilled workforce, and extensive experience in executing large-scale infrastructure projects have enabled several domestic factories to be recognized as reputable HDPE pipe manufacturers. These manufacturers not only meet the demands of the domestic market, but in many cases also supply their products to neighboring countries and export markets.

One of the key characteristics of Iranian manufacturers of high density polyethylene pipes is their compliance with international standards such as ISO 4427, DIN 8074/8075, as well as the Iranian national standard. This compliance has allowed domestically produced pipes to compete with foreign products in terms of quality, pressure rating, and durability. As a result, the use of locally manufactured products in water supply, sewage, agricultural, and industrial projects has become a logical and cost-effective choice.

Polyethylene Kerman

Polyethylene Kerman is one of the most well-known names among domestic HDPE pipe manufacturers. By focusing on the production of HDPE pipes in a wide range of sizes and pressure ratings, this factory covers a significant portion of the needs of water supply and fluid transmission projects. Consistent quality, precise control of the production process, and the use of standard raw materials are among the reasons why this company’s products are widely used in major infrastructure projects.

Pars Ethylene Kish

Pars Ethylene Kish is another active manufacturer in the field of high density polyethylene piping, producing a wide range of HDPE pipes and fittings. With a focus on industrial and semi-industrial projects, this company offers products with various pressure ratings. The presence of this brand in export markets reflects the acceptable quality level of its products and their ability to compete at a regional level.

Arya Polymer Pishgam

Arya Polymer Pishgam is one of the manufacturers that, alongside the production of HDPE pipes, places special emphasis on expanding its range of fittings. This has enabled many contractors to source complete HDPE pipes and fittings systems from a single supplier. The factory’s focus on quality consistency and responsiveness to customized project requirements has made it a reliable option for urban and industrial projects.

Golpayegan Polymer

Golpayegan Polymer also holds a solid position among domestic HDPE pipe manufacturers, and its products are used in water, sewage, and irrigation projects. By producing HDPE pipes across a wide range of HDPE pipe sizes, this factory allows more precise selection based on specific project requirements. Quality consistency and compliance with declared technical specifications are among the key characteristics of this manufacturer.

The Role of the Supplier in Selecting the Right Manufacturer

Despite the diversity of domestic manufacturers, selecting the right factory for each project requires careful evaluation of technical specifications, delivery timelines, after-sales services, and execution experience. At this stage, the role of a professional supplier becomes particularly important. A reliable HDPE pipe supplier, with in-depth knowledge of the Iranian manufacturing market, can recommend the most suitable option based on project type, operating pressure, and budget.

With direct collaboration experience with reputable domestic manufacturers, Shobeir Shimi enables buyers and contractors to access high-quality products with minimal risk. This approach not only helps reduce costs, but also ensures full compliance of the supplied products with the technical requirements of the project. These factories produce a wide range of HDPE pipes and fittings in accordance with national and international standards.

HDPE Pipe Specifications | Technical Specifications of HDPE Pipes

A thorough review of HDPE pipe specifications is one of the most critical steps before selecting and purchasing HDPE pipes for any project. These specifications determine the pipe’s performance under various conditions, including pressure, temperature, fluid type, and installation environment. Ignoring these factors, even when using high-quality pipes, can lead to reduced system lifespan, increased maintenance costs, or operational issues. Therefore, in professional projects, technical specifications always serve as the foundation for HDPE pipe design and selection.

Material Grade | PE80 and PE100

One of the primary elements in HDPE pipe specifications is the material grade. The most commonly used grades in high-density polyethylene pipes are PE80 and PE100. Pipes made from PE100 offer higher strength compared to PE80, enabling thinner walls while maintaining higher pressure tolerance. This feature reduces pipe weight, simplifies transportation, and lowers installation costs.

Choosing the appropriate grade depends on the application. PE100 is typically used in high-pressure pipelines and main transmission projects, whereas PE80 can be a cost-effective solution for lighter applications. Understanding the differences between these grades is crucial for optimizing HDPE piping system design.

Pressure Rating (PN) | Nominal Pressure

The pressure rating (PN) is another key parameter in HDPE pipe specifications. It indicates the maximum pressure the pipe can safely withstand under standard conditions. HDPE pipes are produced in various pressure classes, including PN6, PN10, PN16, and higher. Selecting the correct pressure rating depends on factors such as fluid type, flow rate, pipeline length, and operating conditions.

In municipal water supply and long-distance transmission lines, choosing the right PN is critical. Inadequate pressure resistance can lead to performance drops or pipe damage. Proper pressure selection ensures that non-corrosive PE pipelines operate safely and reliably for decades.

SDR Ratio | Standard Dimension Ratio

The SDR ratio is a crucial specification that describes the relationship between the pipe’s outer diameter and wall thickness. A lower SDR means a thicker wall and higher pressure resistance, making these pipes ideal for high-pressure and industrial applications. Conversely, pipes with higher SDR values are lighter and suitable for lower-pressure uses.

Selecting the correct SDR not only impacts system safety but also affects the overall project cost. Engineers typically determine SDR based on pressure requirements and fluid type to achieve the optimal balance between safety and cost efficiency.

Temperature Range | Operating Temperature

The permissible temperature range is another vital aspect of HDPE pipe specifications. Typically, HDPE pipes perform reliably in temperatures from -40°C to +60°C, making them suitable for diverse climates, from cold regions to hot environments.

However, higher fluid temperatures can affect allowable pressure. For applications with elevated temperatures, pressure correction factors are usually applied during design to prevent long-term operational issues.

Standards & Certifications | Compliance and Quality Assurance

Production standards are key to ensuring the quality and safety of HDPE pipes. Reputable pipes are manufactured according to international standards such as ISO 4427, DIN 8074/8075, and EN 12201. In Iran, national polyethylene pipe standards also serve as a basis for many civil and industrial projects.

Certificates and factory testing guarantee that the final product meets thickness, material uniformity, and pressure tolerance requirements. Reviewing these standards and technical documentation is essential for professional buyers and reliable HDPE pipe suppliers.

Chemical Resistance | Corrosion and Chemical Durability

A significant advantage of HDPE pipes is their excellent chemical resistance. HDPE withstands a wide range of acids, alkalis, and industrial chemicals, making it ideal for chemical, petrochemical, and wastewater applications.

This chemical resistance ensures that non-corrosive PE pipelines perform reliably in corrosive environments without needing protective coatings or frequent maintenance, ultimately reducing operational costs over the project’s lifetime.

HDPE Pipe Specifications Summary

| Feature | Description |

|---|---|

| Material Grade | PE80 / PE100 |

| Pressure Rating (PN) | PN6 to PN16 and higher |

| SDR Ratio | 9 to 33 |

| Temperature Range | -40°C to +60°C |

| Standards | ISO 4427, DIN 8074/8075, EN 12201 |

| Chemical Resistance | Very High |

HDPE Pipes vs Other Materials | Comparative Advantages

Comparing HDPE pipes with common alternatives such as PVC, steel, and concrete helps in making informed decisions. Each material behaves differently under corrosion, pressure, environmental conditions, and maintenance requirements. Choosing the wrong material can increase long-term project costs.

| Pipe Type | Corrosion Resistance | Flexibility | Approx. Lifespan | Maintenance Cost |

|---|---|---|---|---|

| HDPE | Very High | High | 50+ Years | Very Low |

| PVC | Medium | Low | 25–30 Years | Medium |

| Steel | Low | Very Low | 20–25 Years | High |

| Concrete | Medium | Almost None | 30–40 Years | High |

This comparison shows that HDPE pipes offer the best combination of corrosion resistance, flexibility, and longevity while keeping maintenance costs low, making non-corrosive PE pipelines the top choice for modern infrastructure projects.

Installation Guidelines for HDPE Pipes | Proper Installation Practices

Correct installation of HDPE pipes directly affects system performance, safety, and lifespan. Even the highest-quality pipes can fail if installed improperly. Following installation standards, particularly in welding and joint quality control, ensures that HDPE pipe supply systems function reliably throughout their designed life.

Key Installation Practices

- Using Standard Welding Equipment

Reliable joints require calibrated, standard welding machines. Non-standard equipment cannot maintain uniform temperature or pressure, compromising joint strength. Regular calibration and checks are essential for professional projects.

- Controlling Welding Temperature

Plate temperatures should match the pipe grade and size. Excess heat can degrade polyethylene, while low temperatures result in weak joints. Proper temperature control ensures the joint withstands system pressure reliably.

- Cleaning Connection Surfaces

All surfaces must be free of dust, moisture, or grease before welding. Surface contamination weakens the weld and increases the risk of leaks. This simple step plays a critical role in ensuring final system integrity.

- Pressure Testing After Installation

After installation, pressure testing confirms joint integrity. Identifying leaks or defects before commissioning prevents costly future issues.

HDPE Pipe Price Analysis

HDPE pipe price depends on multiple technical and economic factors rather than size alone.

Key Price Factors

- Raw material cost: PE80 and PE100 resin prices directly affect cost

- Exchange rate: Especially relevant for export projects

- Pipe size & SDR: Thicker walls require more material

- Application: Water, gas, or sewage standards vary

- Order volume: Bulk orders reduce unit cost

Why HDPE Is Cost-Effective

Although initial HDPE pipe costs may be higher in some cases, minimal maintenance, long service life, and corrosion resistance significantly reduce total project cost over time.

HDPE Pipe Supplier & Supply Chain

Choosing the right HDPE pipe supplier is essential for project success. A professional supplier ensures continuous availability, technical support, transparent pricing, and reliable logistics.

Shobeir Shimi plays a key role in HDPE pipe supply for industrial, infrastructure, and export projects. With direct access to trusted domestic and international manufacturers, the company provides stable supply, expert technical consultation, and competitive pricing.

Features of a Professional HDPE Pipe Supplier

Continuous Supply

A reliable supplier must have the capacity to provide a consistent supply of HDPE pipes and fittings throughout the project duration. Any disruption can halt operations and increase project costs, especially in large-scale, time-sensitive projects.

Technical Consultation

A professional HDPE pipe supplier is more than just a vendor. By offering technical guidance on pipe size, SDR, application type, and suitable fittings, they help optimize system design and minimize execution risks.

Competitive and Transparent Pricing

Transparent, competitive pricing allows accurate cost estimation for both contractors and clients. This transparency is crucial for effective budget management and informed economic decision-making in projects.

Experience with Large Projects

Experience in industrial, infrastructure, and construction projects demonstrates a supplier’s capability to manage large orders, coordinate technical requirements, and respond effectively in complex situations.

Shobeir Shimi | Specialized HDPE Pipe Supplier

Shobeir Shimi leverages direct access to reputable domestic and international manufacturers, playing a key role in the HDPE pipe supply chain for industrial, infrastructure, and export projects. The company focuses on sustainable supply, specialized technical consultation, and transparent pricing, enabling contractors and clients to select HDPE pipes and fittings precisely according to their project needs.

FAQ | Frequently Asked Questions About HDPE Pipe

- What does HDPE pipe mean?

HDPE pipe refers to piping manufactured from high-density polyethylene, designed for high-performance fluid transmission. - How are HDPE pipe sizes selected?

Selection depends on flow rate, pressure, application type, and installation conditions. - Are HDPE pipes only for water?

No, they are used for sewage, chemicals, industrial fluids, and drainage systems. - What role do HDPE pipe fittings play?

They ensure safe connections, flow control, and system integrity. - How long do HDPE pipes last?

With proper design and installation, service life can exceed several decades. - Why are HDPE pipe diameters important?

Wide diameter ranges allow use in both small and large-scale projects. - How do I choose an HDPE pipe supplier?

Look for supply reliability, technical expertise, and proven project experience.

Conclusion

High Density Polyethylene (HDPE) pipes have become one of the most reliable and widely used solutions in water supply, sewage, drainage, and industrial fluid transportation projects. Their full range of sizes and SDR ratings, wide availability of HDPE pipe fittings, high resistance to corrosion and chemicals, and long service life make HDPE piping systems a technically and economically sound choice for modern projects.

Beyond product quality, the informed selection of HDPE pipe manufacturers and collaboration with a reputable HDPE pipe supplier play a decisive role in project success. Continuous supply, strict adherence to technical specifications, and access to expert consultation are key factors in minimizing execution risks. In this regard, Shobeir Shimi, with direct access to domestic and international manufacturers and a professional approach to the supply chain, can serve as a reliable partner for projects of any scale, from small local works to large industrial or export projects.

Leave A Comment