In the rapidly evolving landscape of modern agriculture, the demand for high-efficiency inputs has never been greater. Among the various sources of nitrogen, granular urea stands out as the preferred solid fertilizer for large-scale, mechanized farming. With a high concentration of 46% nitrogen and superior physical properties, it is the cornerstone of yield maximization for crops worldwide.

For agricultural distributors, fertilizer blenders, and industrial procurement managers, securing a reliable urea fertilizer granular supplier is not just about purchasing a commodity; it is about ensuring supply chain stability and product integrity. As a leading granular urea manufacturer and exporter, we provide premium-grade nitrogen solutions designed to meet the rigorous demands of the global market. This guide explores the technical specifications, the urea granulation process, and the strategic advantages of partnering with a top-tier granular urea bulk supplier.

What is Granular Urea 46%? Definition and Composition

Granular Urea is a premium solid nitrogen fertilizer containing a minimum of 46% nitrogen by weight. Also chemically known as Carbamide or Carbonyldiamide, it holds the distinction of having the highest nitrogen content of any solid nitrogen fertilizer on the market.

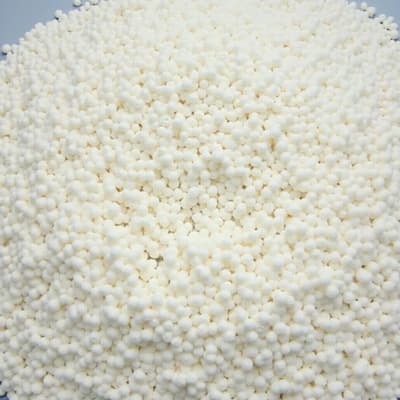

While it shares the standard chemical formula CH4N2O (or CO(NH2)2) with other forms of urea, Granular Urea is engineered specifically for modern, large-scale agriculture. Unlike its prilled counterpart, which is smaller and softer, granular urea is produced as larger, harder granules, typically ranging from 2mm to 4mm in diameter.

Chemical Composition & Physical Structure

From a chemical perspective, Granular Urea is synthesized by reacting Ammonia (NH3) and Carbon Dioxide (CO2) under controlled high-pressure and temperature conditions.

Its physical structure is optimized for global logistics and precise application:

- High Solubility: It is highly soluble in water, allowing for rapid interaction with soil enzymes to release nutrients.

- Bulk Density: With a density of approximately 700–750 kg/m³ (46.8 lb/ft³), it maximizes storage efficiency.

- Free-Flowing: The uniform granule size ensures the product flows smoothly through mechanical spreaders without clogging.

The Urea Granulation Process: Engineered for Durability

The superiority of high-quality Granular Urea stems directly from its manufacturing method, known as Fluidized Bed Granulation. This sophisticated technique differs significantly from simple prilling.

In this process, molten urea is sprayed onto seed granules suspended within a fluidized bed granulator. Crucially, a conditioning agent (typically formaldehyde) is often added to the melt. As the seeds rotate in the air, layers of molten urea solidify around them, building up the granule size in a dense “onion-skin” structure.

Why this matters:

- Crushing Strength: The layered structure and hardening agents make the granules highly resistant to crushing and abrasion.

- Dust Control: It arrives at the destination with minimal dust, ensuring product integrity during international shipping.

- Moisture Resistance: The hard outer shell reduces hygroscopicity (moisture absorption), preventing the caking issues often seen in prilled urea.

Granular Urea vs. Prilled Urea: Why Choose Granular?

For buyers deciding between Granular Urea and Prilled Urea, the choice often depends on the intended application. While both provide 46% Nitrogen, Granular Urea offers distinct logistical and agronomic advantages, making it the industry standard for commercial agriculture and bulk blending.

1. Superior Hardness & Logistics Integrity

The primary commercial advantage of granular urea is its high crushing strength. Unlike prilled urea, which is softer and prone to breaking, granular urea is engineered to withstand the high pressures of bulk storage and ocean transport.

- Dust Reduction: Harder granules generate significantly less dust during handling. This not only preserves air quality but also prevents product loss (shrinkage) during loading and unloading.

- Storage Stability: Its resistance to moisture absorption (hygroscopicity) is superior, significantly reducing the risk of caking in warehouses.

2. Optimized for Bulk Blending (NPK)

Granular Urea is the essential nitrogen component for producing high-quality NPK blends.

- Particle Size Compatibility: With a uniform size range of 2-4mm, it closely matches the particle size of other major fertilizers like DAP (Diammonium Phosphate) and MAP (Monoammonium Phosphate).

- Preventing Segregation: In fertilizer blends, particles of different sizes tend to separate during transport (segregation). Because Granular Urea matches the size of phosphates and potash, the blend remains uniform from the factory to the farm, ensuring crops receive a balanced diet.3. Precision in Mechanical Spreading

Modern farming relies on broad-width, high-speed spreaders.

- Aerodynamics: The larger, heavier particles of granular urea have better ballistic properties. They can be thrown further and more evenly across the field.

- Wind Resistance: Granules are less susceptible to wind drift compared to lighter prills. This ensures the nitrogen lands exactly where it is needed, rather than blowing into neighboring fields or ditches.

4. Improved Nitrogen Use Efficiency (NUE)

While urea is generally fast-acting, the physical structure of granules offers a slight agronomic edge:

- Slower Dissolution: Due to a smaller surface-area-to-volume ratio compared to fine prills, granules dissolve slightly slower. This can help reduce immediate nitrogen loss through volatilization (gassing off) and leaching, providing a more sustained nutrient supply to the crop.

Technical Specifications & Data Sheet (TDS)

When sourcing Granular Urea for export, verifying the technical data is paramount. We strictly adhere to international standards to ensure our specifications meet the rigorous needs of both industrial buyers and agricultural distributors.

Our product is sourced directly from top-tier petrochemical producers (including Pardis, Lordegan, and Shiraz Petrochemical Companies), ensuring consistent purity and physical durability.

Standard Specification Sheet

Below is the guaranteed analysis for our Export-Grade Granular Urea:

| Parameter | Specification | Note |

|---|---|---|

| Nitrogen Content | 46.0% Min | Industry Standard N46 |

| Biuret | 1.0% Max | Low biuret prevents plant toxicity |

| Moisture | 0.5% Max | Critical to prevent caking |

| Particle Size | 2 – 4 mm | 90-95% Uniformity |

| Crushing Strength | 3kg Min | High hardness guaranteed |

| Formaldehyde | ~ 0.5% | Conditioning agent for hardness |

| Color | Pure White | Free from impurities |

| HS Code | 3102.10 | Granular urea HS Code for customs |

Understanding the Key Parameters

1. Nitrogen Content & Purity

We confirm that our product is 46% Nitrogen Granular Urea, offering the highest nitrogen concentration available in solid fertilizers. This high purity ensures maximum efficiency for crops and optimal yield for chemical synthesis.

2. Biuret Control (Safety for Crops)

Biuret is a byproduct formed during urea manufacturing. High levels of biuret can be toxic to germinating seeds and sensitive foliage (phytotoxicity).

- Our Standard: We maintain biuret levels strictly below 1.0%. This makes our urea safe for soil application and minimizes risks during seed placement.

3. Moisture & Anti-Caking

To ensure the cargo arrives in free-flowing condition, our urea undergoes rigorous moisture control (Max 0.5%) and is treated with formaldehyde. This treatment hardens the granule and creates a hydrophobic barrier, preventing the product from absorbing humidity and clumping inside the vessel or bags.

4. Third-Party Inspection (SGS/Bureau Veritas)

Quality is not just a claim; it is a guarantee. All our shipments are subject to inspection by internationally recognized agencies like SGS or Bureau Veritas at the port of loading. They verify:

- Weight and Quantity.

- Physical properties (Size, Color).

- Chemical analysis (Nitrogen, Biuret, Moisture) against the datasheet.

Key Applications: Benefits of Granular Urea in Farming & Industry

The versatility of Granular Urea drives its massive global demand. Understanding its diverse uses helps buyers calculate the Return on Investment (ROI) for their specific sector.

Agriculture: Optimized for Modern Farming

Is Granular Urea suitable for agriculture? Absolutely. It is the global standard for high-yield crops like Corn (Maize), Wheat, Rice, Cotton, and Sugar Cane.

- Mechanized Application: Granular urea is the best choice for machine spreading. Its density and aerodynamic properties allow it to be thrown further and more evenly by broad-width spreaders, reducing the number of passes required across the field.

- Precision Bulk Blending (NPK): For fertilizer blenders, segregation (separation of nutrients) is a major concern. Because urea granules (2-4mm) are similar in size to Phosphate (DAP/MAP) and Potash granules, the final blend remains uniform from the factory to the farm, ensuring balanced nutrition for every plant.

- Controlled Dissolution: While urea is generally fast-acting, granules have a lower surface-area-to-volume ratio compared to fine prills. This results in a slightly slower dissolution rate, which can reduce immediate nitrogen loss through leaching and volatilization, providing a more sustained nutrient release.

Industrial & Technical Uses

Beyond the field, Technical Grade Granular Urea is utilized in various chemical processes where high purity and ease of handling are required.

- AdBlue / DEF Production: High-purity urea is the raw material for producing Diesel Exhaust Fluid (DEF) or AdBlue. This solution is injected into diesel engines (SCR systems) to break down harmful NOx emissions into harmless nitrogen and water.

- Emission Control (SNCR): Granular urea is widely used in industrial power plants and incinerators for SNCR (Selective Non-Catalytic Reduction) systems to reduce nitrogen oxide pollutants.

- Chemical Synthesis: It serves as a primary feedstock for the production of:

- Melamine: Used in laminates and kitchenware.

- Resins & Adhesives: Specifically Urea-Formaldehyde (UF) resins used in the manufacturing of plywood, particleboard, and MDF.

Global Market & Sourcing: Manufacturers and Suppliers

The Granular Urea market is dynamic, heavily influenced by energy costs and global logistics capabilities. Shobeir Shimi, as a premier Iranian petrochemical exporter, provides a stable, reliable bridge between major production hubs and buyers worldwide.

Key Production Hubs: Middle East & Iran

The Middle East dominates global nitrogen production due to its abundant reserves of Natural Gas, the primary feedstock for urea manufacturing. This access allows for continuous production and competitive pricing compared to other regions.

We source directly from Iran’s top-tier petrochemical complexes, ensuring you receive fresh, high-specification product without unnecessary intermediaries. Our supply network includes:

- Pardis Petrochemical Co.

- Lordegan Petrochemical Co.

- Shiraz Petrochemical Co.

- Kermanshah Petrochemical Industries

Supply Chain & Export Logistics

Moving bulk fertilizer requires precision. Shobeir Shimi manages a robust supply chain, moving Granular Urea efficiently from factory silos to your local port.

- Loading Ports: We operate from major hubs including Bandar Abbas, Assaluyeh, and Imam Khomeini Port (BIK).

- Flexible Incoterms: We offer terms tailored to your needs, including FOB (Free On Board), CFR (Cost and Freight), and CIF (Cost, Insurance, and Freight).

- Global Delivery: Whether you need containerized shipments for smaller lots or Bulk Vessel Charters (Handymax/Supramax) for large volumes (30,000+ MT), our logistics team handles the complexities of ocean freight to South America, Africa, and Asia.

groscopic.

Packaging & Storage Solutions

Proper packaging is the final step in quality assurance, specifically designed to protect urea from moisture during long ocean transits. We offer:

| Packaging Type | Description | Best For |

|---|---|---|

| Bulk | Loose inside vessel holds or bulk-lined containers. | Large Industrial Buyers & High Volume Agriculture |

| Jumbo Bags (FIBC) | 1-Ton or 1.5-Ton Big Bags with inner PE liners and UV protection. | Distributors & Large Farms |

| Small Bags | 50kg laminated PP/PE bags (Palletized or Loose). | Local Retail & Small-Scale Application |

Storage Recommendation: Urea is hygroscopic (attracts moisture). To maintain quality, store the product in a cool, dry, and well-ventilated warehouse. Ensure bags are kept off the ground (on pallets) and away from direct sunlight.

Buying Guide: Pricing & Selection

Ready to buy Granular Urea? Here is what procurement managers need to know to make an informed decision.

Factors Influencing Granular Urea Price

The price of urea is never static. It fluctuates based on three main drivers:

- Energy Costs: Since natural gas accounts for ~70-80% of production costs, gas price indices directly impact the FOB price.

- Seasonal Demand: Prices often spike during key planting seasons in the Northern Hemisphere (Spring) and Southern Hemisphere (Fall).

- Freight Rates: Ocean freight indices (like the BDI) impact the final CFR/CIF landed cost.

Why Partner with Shobeir Shimi?

When selecting a Granular Urea distributor, you need more than just a price; you need a partner.

- Proven Track Record: Years of experience in petrochemical export.

- Inspection Guarantee: We provide SGS or Bureau Veritas inspection reports for every shipment to verify Quality (N46%) and Quantity.

- Direct Access: By cutting out multiple brokers, we offer the most competitive rates from the source.

Ready to Order?

Contact our sales team today for the latest price offer and shipping schedule.

FAQ: Common Questions About Granular Urea

Conclusion: Secure High-Quality Granular Urea for Your Market

In the competitive landscape of global agribusiness, the quality of your inputs defines the profitability of your output. Granular Urea 46% stands as the superior choice for modern agriculture, offering the perfect balance of high nitrogen density, physical durability, and logistical efficiency.

However, securing a consistent supply chain is just as critical as the product itself. At Shobeir Shimi, we don’t just sell fertilizer; we deliver stability. With over two decades of experience (since 2004) and direct access to Iran’s largest petrochemical complexes, we bridge the gap between production hubs and your local port.

Why Secure Your Supply with Us?

- Manufacturer-Direct Pricing: We cut out unnecessary intermediaries to offer you the most competitive market rates.

- Quality Guarantee: Every shipment is backed by third-party inspection reports (SGS/Bureau Veritas) to ensure N46 purity and physical integrity.

- Global Reach: Whether you need FOB delivery in the Persian Gulf or CIF delivery to South America, Africa, or Asia, our logistics team handles the complexities of international trade for you.

Don’t let supply chain volatility disrupt your business. Partner with a trusted Granular Urea bulk supplier today.