Yes, absolutely. In fact, the ability to be bent is one of the most powerful properties of High-Density Polyethylene (HDPE). Unlike rigid, inflexible materials such as concrete, ductile iron, or even PVC, HDPE’s unique molecular structure gives it a remarkable combination of strength and elasticity. This HDPE pipe flexibility is a primary driver of its adoption in municipal, industrial, and agricultural sectors, allowing it to be installed in complex environments, navigating around obstacles, and following natural contours.

But this flexibility is not unlimited. Simply knowing that HDPE can be bent isn’t enough; safe, long-term installation depends on how it’s bent. This guide will provide a definitive overview of HDPE’s flexibility, detail the crucial HDPE minimum bend radius calculation formulas, and outline the best practices for achieving safe, long-lasting bends in both pipe and sheet. As a general rule of thumb, HDPE pipe can typically be bent to a radius 20 to 25 times its outside diameter, a fact that fundamentally changes installation logic and cost.

Understanding Why Flexibility is HDPE’s Core Advantage

Choosing an HDPE flexible pipe system is a strategic decision that delivers significant advantages in cost, installation speed, and long-term durability. The material’s unique molecular structure allows it to withstand stresses that would cause more brittle materials to fail.

Reduced Cost and Labor (Eliminating Fittings)

In a traditional piping installation with rigid materials, every change in direction—no matter how small—requires a fitting. This means crews must excavate a larger area, cut the pipe, de-burr the edges, install a 45° or 90° elbow, and create two new joints. Each joint is a potential leak point and adds significant time and labor to the project.

With flexible HDPE tube, the pipe can “lilt” or sweep into gradual turns. This allows installers to lay the pipe in a curving trench, avoiding obstacles like trees, manholes, or other utilities without a single fitting. This not only simplifies and speeds up construction but also enhances system integrity by eliminating potential points of failure.

When a fitting is unavoidable, the system’s integrity is maintained through permanent, leak-free HDPE thermal fusion welding that fuses the pipe and fitting into a single, monolithic piece.

Resilience to Environmental and Ground Stress

The ground is not static. Shifting soils, freeze-thaw cycles, heavy surface traffic, and even minor seismic activity all place immense stress on buried pipelines.

- Rigid Materials (PVC, Iron): These materials absorb stress directly. A shifting-soil load or a tremor can concentrate force on a rigid pipe or joint, leading to cracks and catastrophic failure.

- Flexible HDPE: HDPE’s ductility allows it to absorb and disperse these stresses. When the ground shifts, the flexible pipe moves with it, deforming slightly and then returning to its original shape. This makes it the material of choice for unstable soil conditions and seismically active regions, as the pipe is far less prone to cracking or joint failure.

HDPE vs. PVC Bending Capabilities

The comparison between HDPE and PVC highlights this difference starkly.

- PVC (Polyvinyl Chloride): A rigid, amorphous polymer. It is strong but brittle, especially in cold weather. While it can be bent using specialized heating methods (like packing it with hot sand or salt), this is a fabrication process, not an inherent installation feature. Bending PVC on-site without heat is impossible.

- HDPE (High-Density Polyethylene): A semi-crystalline polymer. Its long-chain molecular structure provides superior ductility and toughness, even at very low temperatures where PVC would shatter on impact. This inherent plasticity is what allows for “cold bending” during installation.

The Technical Limits: Defining the HDPE Minimum Bend Radius

The flexibility of HDPE is its greatest asset, but it must be controlled. The HDPE minimum bend radius is the most critical technical limit an installer must respect.

What is the Minimum Bend Radius?

The HDPE bend radius is defined as the smallest radius a pipe can be bent without causing kinking, damage, degradation, or a loss of long-term structural integrity.

If a pipe is “over-bent” (bent to a radius smaller than the minimum), it can lead to kinking (a collapse of the pipe wall) or induce long-term stress that will shorten its service life. This value is not arbitrary; it is a calculated limit based on two key factors:

- Pipe Outer Diameter (OD): A larger pipe is harder to bend and requires a wider radius.

- Standard Dimension Ratio (SDR or DR): This is the ratio of the pipe’s outside diameter to its wall thickness. A lower SDR (e.g., SDR 9) means a thicker pipe wall. A higher SDR (e.g., SDR 17) means a thinner pipe wall.

Long-term vs. Short-term Curvature (Critical Distinction)

The allowable bend radius changes based on the duration of the bend. This is a critical distinction for engineers and installers.

- Long-term Bend Radius: This is the minimum radius the pipe can be bent to for its permanent, in-service condition (i.e., for years or decades). This is the more conservative, wider radius used for designing the pipe’s final resting place in a trench.

- Short-term (Field) Bend Radius: This is a tighter, more aggressive radius that is allowable only for short-term installation procedures. This is common in directional drilling or when pulling pipe through a conduit. The pipe can withstand this higher stress for a brief period, but it must not be left in this state.

Step-by-Step HDPE Bending Calculations and Formulas

Calculating the minimum bend radius is straightforward and essential for any project plan.

The Fundamental Bend Radius Formula

The governing equation for the HDPE pipe bending radius calculation is:

R = a(OD)

Where:

- R = Minimum Bend Radius (in inches or cm)

- a = Minimum Allowable Bend Ratio (a dimensionless factor)

- OD = Pipe Outside Diameter (in the same units as R)

The entire calculation comes down to finding the correct “a” factor for your pipe.

Calculating the Recommended Long-Term Bend Radius (by DR/SDR)

The bend ratio “a” is determined by the pipe’s SDR/DR. It’s important to understand a key (and sometimes counter-intuitive) relationship: thicker-walled pipes (lower SDR) can be bent to a tighter radius than thinner-walled pipes.

Why? The thick wall provides the structural strength to resist kinking and collapse during the bend. A thin-walled pipe is more flexible but also more prone to buckling, so it requires a more gentle (wider) bend.

Here is a table of common minimum long-term bend ratios (“a”) based on pipe DR/SDR and material (PE4710).

| Pipe Dimension Ratio (DR/SDR) | Minimum Bend Ratio (a) | Example: 12″ Pipe (12.75″ OD) |

|---|---|---|

| DR 7 / 7.3 (Thickest Wall) | 20 | 20 x 12.75″ = 255″ (21.3 ft) |

| DR 9 | 20 | 20 x 12.75″ = 255″ (21.3 ft) |

| DR 11 | 25 | 25 x 12.75″ = 319″ (26.6 ft) |

| DR 13.5 | 25 | 25 x 12.75″ = 319″ (26.6 ft) |

| DR 15.5 | 27 | 27 x 12.75″ = 344″ (28.7 ft) |

| Gallery-formatted: | – | – |

| DR 17 (Thinnest Wall) | 27 | 27 x 12.75″ = 344″ (28.7 ft) |

The Influence of Temperature and Thermal Expansion

Temperature plays a major role. The minimum bend radius values are typically given for a standard laying temperature of 20°C (68°F).

- Cold Weather: As the temperature drops, HDPE becomes stiffer. In very cold conditions (e.g., 0°C or 32°F), the allowable bend radius increases (the bend must be wider and more gradual).

- Thermal Expansion: Installers must also account for HDPE thermal expansion and bending. A pipe laid in the heat of the day will contract and pull as it cools overnight. This stress, combined with bending, must be managed. Bending points must be securely fixed and supported to prevent springback and ensure the pipe stays in place.

Practical Methods: HDPE Cold Bending vs. Hot Bending

There are two distinct ways to achieve HDPE curvature, used for entirely different purposes.

Cold Bending (The Standard Installation Bend)

This is not a “method” so much as a standard feature of HDPE installation. HDPE cold bending simply utilizes the pipe’s inherent flexibility without any heat.

- Use Case: Ideal for small-angle, long-distance curves to follow roads or navigate gentle terrain.

- Construction Precautions:

- Do not attempt to cold bend in environments below -10°C (14°F) without consulting the manufacturer, as the material becomes significantly harder.

- Fixing and support at bending points are mandatory to prevent the pipe from “springing back” and pulling out of position.

Hot Bending (Achieving Precise Curvature)

HDPE hot bending is a fabrication process, not an installation technique. It is used to create specific, sharp, and permanent bends that are not possible with cold bending.

- Use Case: Creating custom fittings, 90° elbows, or complex manifolds in a workshop.

- Process: The pipe section is heated to its “viscous state” (around 110–120°C / 230-248°F) until it becomes soft. It is then forced around a mold and held in place until it cools.

- Benefits: This method allows for a much-reduced bending radius, often as low as 10 times the outer diameter (e.g., for SDR17).

- Methods:

- Industrial: A molding or pipe-bending machine with internal/external supports.

- DIY/Home: A building hot air gun or hair dryer (for very small tubing). A gas hand burner is not recommended as it is difficult to heat uniformly.

- Timing: The heating must be quick and uniform. For a molding machine, bending time may be only 40 seconds for a 90mm pipe or 60 seconds for a 160mm pipe.

How to Bend HDPE Pipe Safely and Prevent Damage

When hot bending, safety and material integrity are paramount.

- Fume Risk: Heating thermoplastics like HDPE can cause degradation and release potentially toxic fumes. Always work in a well-ventilated area and consider personal protective equipment (gloves, and for intense, repeated work, a respirator with an ABEK filter).

- Uniform Heat: The most common mistake is heating only one side of the pipe. This creates a weak, stretched-out “heel.” You must heat the workpiece uniformly, scrolling it around its longitudinal axis, to ensure the entire section is plasticized.

- Risk Mitigation: The goal is to achieve the minimum bending radius of polyethylene pipes without compromising the wall. Uniform heating and proper support are the only way.

Critical Limits and Related HDPE Applications

Knowing the limits is just as important as knowing the techniques.

Understanding HDPE Pipe Strain Limits

What happens if HDPE pipe is over-bent?

- Kinking: The pipe wall collapses on itself, creating a permanent-flow obstruction and a critical weak point.

- Stress Concentration: The outer wall of the bend is stretched thin, while the inner wall is compressed. Bending too tightly creates extreme stress concentration, making this point highly susceptible to cracking or failure years into its service life.

- Springback: If a bend (hot or cold) is not properly cooled and fixed in place, the material’s “memory” will cause it to pull out, ruining the desired angle.

Differentiating HDPE Pipe vs. Sheet Bending

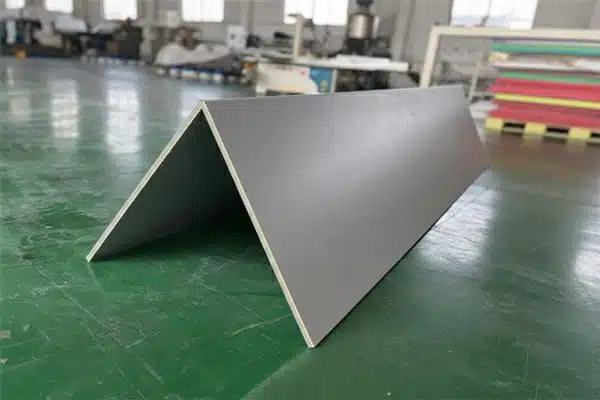

It’s important to note that HDPE sheet bending is a different process from pipe bending. This is a common content gap.

- Pipe Bending: Involves managing a hollow, cylindrical shape and preventing its collapse.

- Sheet Bending: Involves bending a solid plank of material, often to create sharp angles for tanks, scrubbers, or boxes. This is done by heating a very localized, straight line (often with a “heated sword” or heating element) or by using mechanical aids like V-groove cuts to create a hinge for a 90° bend.

Conclusion

So, can HDPE be bent? The answer is a definitive yes. Its unique combination of high strength and practical elasticity makes it the ideal material for modern piping systems, especially in complex or unstable terrain. Its ability to be laid in long, continuous lengths and bent to follow natural contours saves time, money, and, most importantly, eliminates countless potential leak points.

But the more important question is how to bend it safely. To harness this power, one must respect the material’s engineered limits. Adhering strictly to the HDPE bending calculations and formulas—specifically the minimum bend radius based on the pipe’s OD and DR/SDR—is not just a recommendation; it is the key to ensuring the system’s reliability and 100-year service life.

To clarify the minimum bend radius, imagine a rubber band. You can stretch and curve the rubber band (HDPE pipe) significantly without breaking it—this is its flexibility. However, if you try to loop the rubber band tightly around your pinky finger (pushing past the calculated minimum bend radius), it might snap or crease permanently. The minimum bend radius is the safety limit, ensuring you use the material’s elasticity without damaging its structural integrity for the long haul.

Leave A Comment